Whether you sell your products online or via the shelves of your retail store, the allure and appeal of your products’ packaging can have a monumental impact on sales and brand awareness. In most cases, the packaging information on the squeeze tubes is printed. There are also some cases where squeeze tubes need to be labeled, and VKPAK can supply tube labeling machines from semi-automatic to fully automatic.

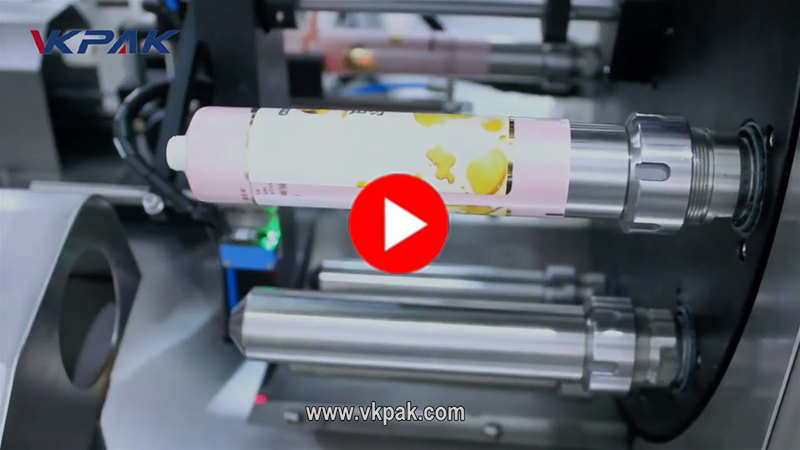

Squeeze tube labeling is different from ordinary tube labeling, squeeze tubes have low rigidity, the problem to be solved for soft tube labeling is how to fix the tube, VKPAK's solution is to use a mold placed in the empty tube, and then roll the mold as well as the tube with the labeling head to complete the labeling. One label or two labels can be applied.

Squeeze Tube Labeling Machine Videos

VK-T805 Semi Automatic Soft Tube Labeling Machine

VK-STL Automatic Empty Soft Tube Labeling Machine

The VKPAK soft tube labeller series is a range of machines that apply self-adhesive labels onto flexible squeeze tubes, at high-speed and with great accuracy. The labellers are in use all around the world, by many leading manufacturers of personal care products and flexible plastic packaging manufacturers alike, who are all finding greater efficiency benefits of labelling squeeze-tubes with self-adhesive labels, over traditional screen printing.

All tube labellers are custom built to meet the exacting demands of the manufacturers and suppliers. They can be used stand alone or integrated in-line, matching filling equipment speeds and one or two labels can be applied in registration. Our labelling machines are installed all over the world, including Europe, USA and Asia.

Benefits of Tube Labelling

- Low inventory of tubes

- Low wastage

- Low cost of tubes

- High quality graphics at lower cost

- Use paper, film or metalised labels

- Accurate product colour matching

- Tactile raised printing options

- Economic for short or long runs