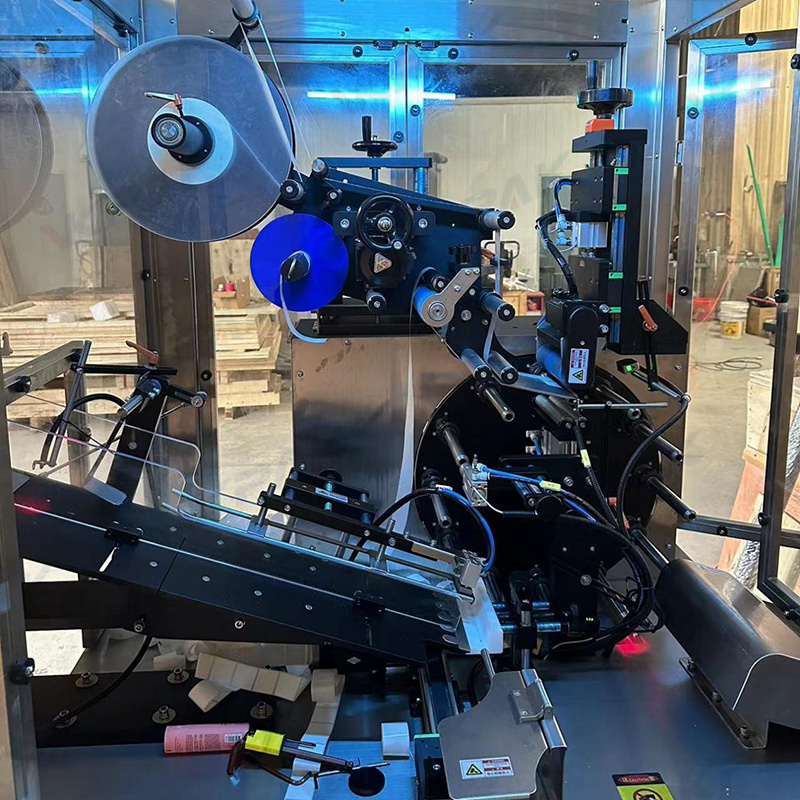

VK-STL Automatic Empty Soft Tube Labeling Machine

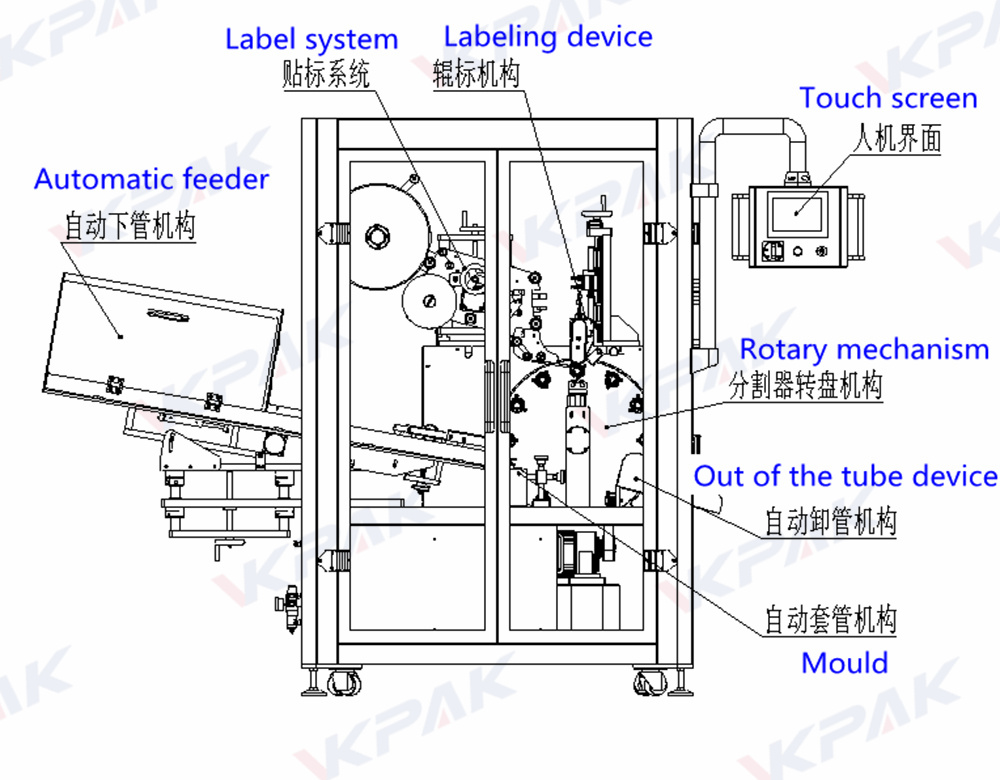

Automatic soft tube labeling machine is the use of self-adhesive roll labeling paper, labeling using the roll labeling method, can be equipped with automatic feeding tube, a complete release, labeling, but also can be equipped with printing machine synchronization to complete the label printing.

This machine adopts computerized fiber optic control, synchronized tracking, and the marking out is controlled by mutual sensing stepping motor, which ensures that the speed of marking out is synchronized with the speed of bottle roll-up as an automated packaging machine. It is a modern electromechanical integration product with excellent and reliable working performance.

Output Speed: 30~ 50 pieces/min

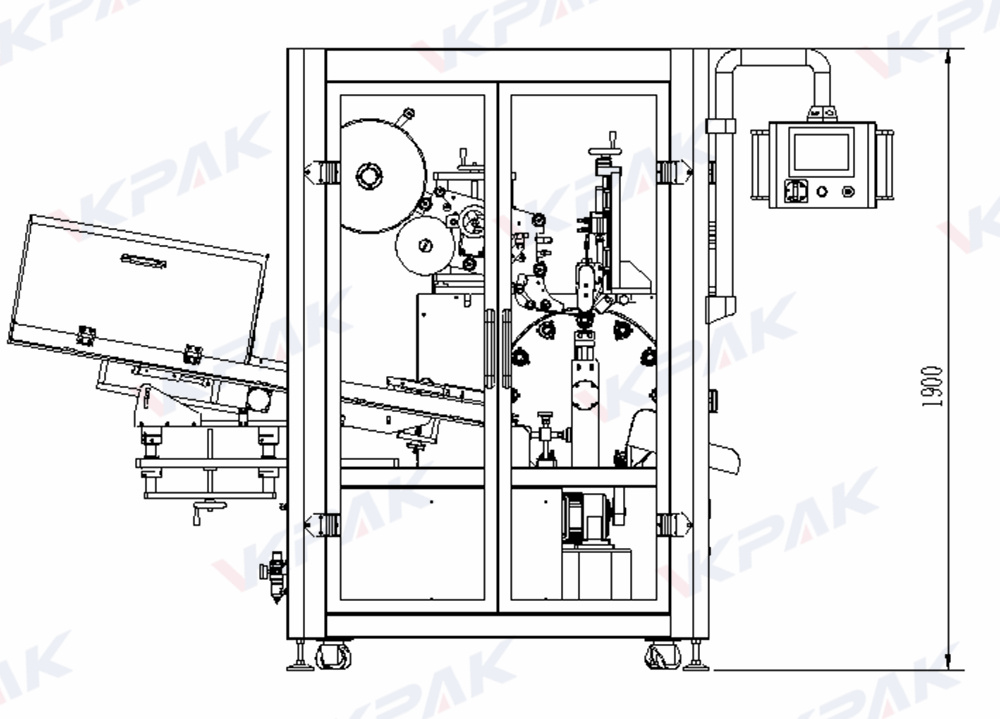

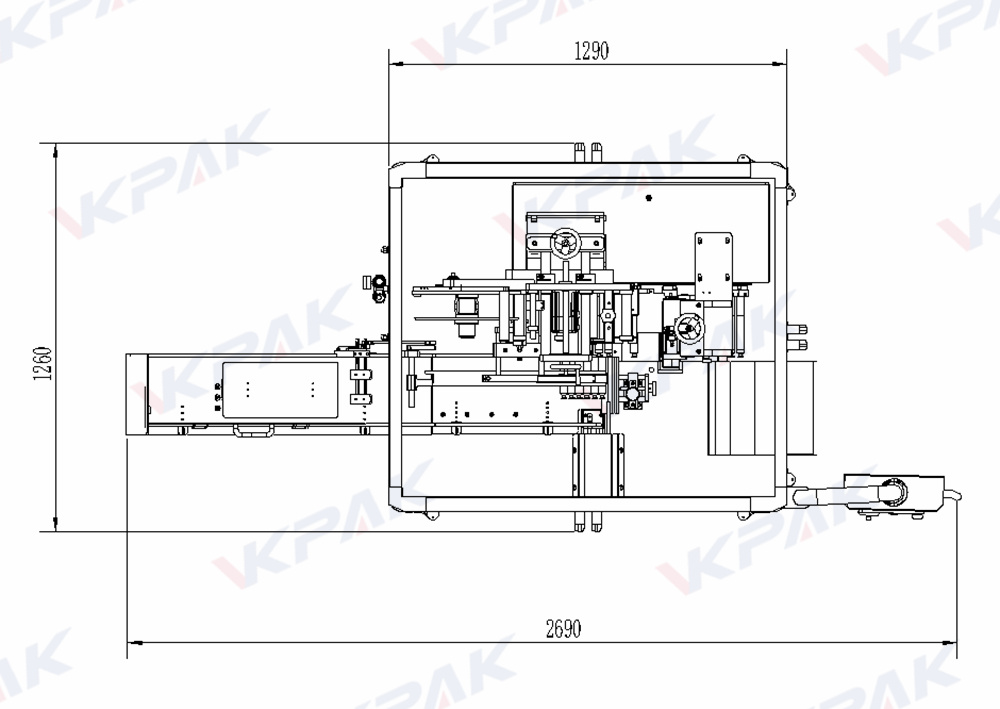

Dimension: L2500mm*W1200mm*H1800mm

With PLC control panel, it is easy to set parameters and debug machine. Language of panel can be customized as your need.

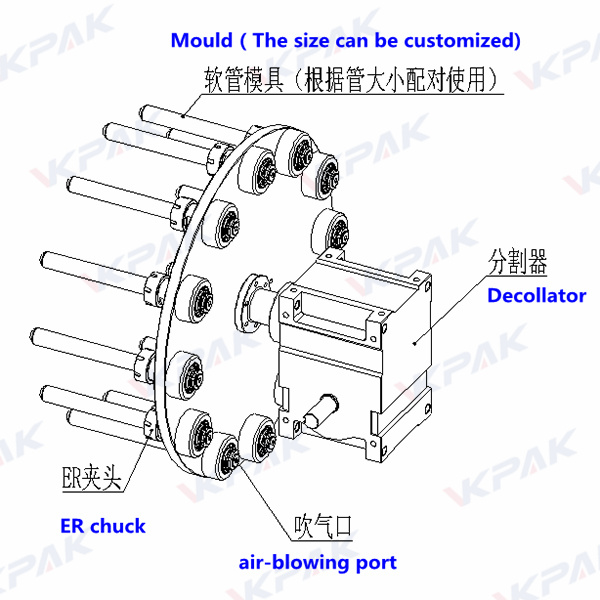

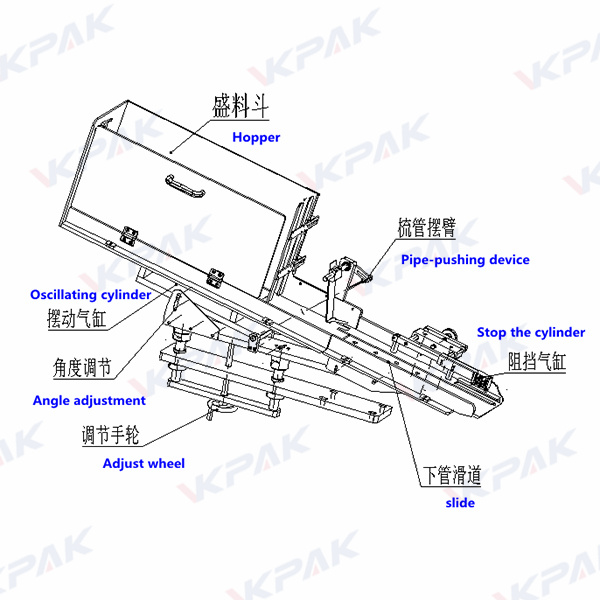

The structure is designed for feeding soft tubes automatically, saving labor cost. It can be customized according to tube size.

The molds can fix tubes during labeling and blow air to unload tubes after labeling. It can be customized according to production need.

With high-quality sensor to detect labels, it can prevent from missing or wasting labels, ensuring labeling accuracy.

Parameter

| Model | VK-STL |

| Labeling speed (pcs/hour) | 1800-2500pcs/hour (relate to material and label size) |

| Labeling accuracy(mm) | ±1.0mm (material and label sizes are not counted in) |

| Label size(mm) | (L)10-300mm (H)10-200mm |

| Material size (mm) | (diameter )φ19-50mm |

| Roll inside(mm) | φ76mm |

| Roll outer diameter(mm) | Max:Φ300mm |

| Machine size (mm) | (L)2500*(W)1200*(H)1800(mm) |

| Power supply | AC220V 50Hz/60Hz 1200W |

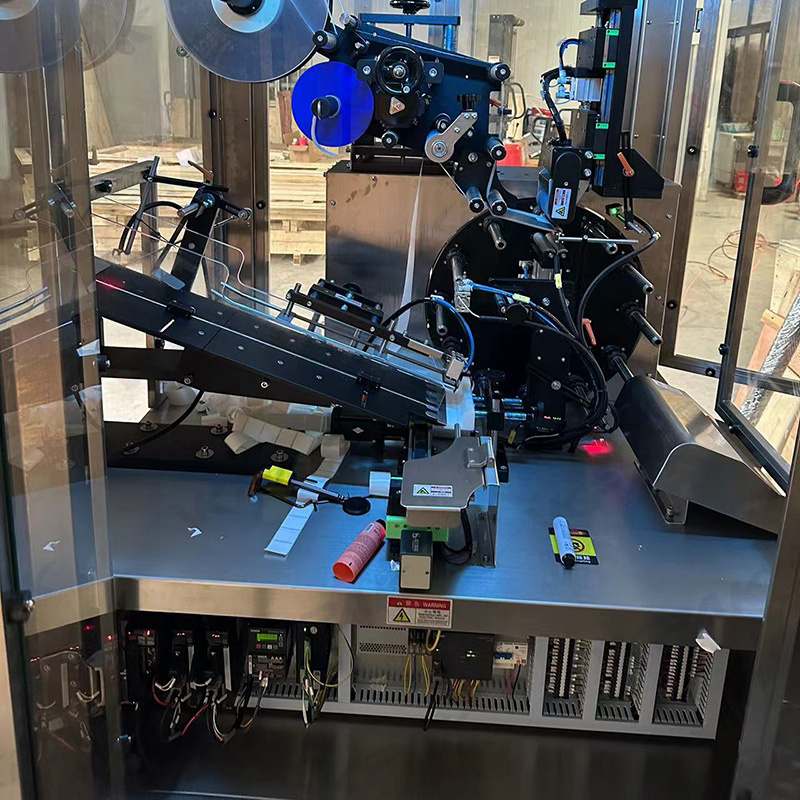

- The main materials are SUS304 stainless steel and imported aluminum alloy in accordance with international standards.

- The surface of aluminum alloy is treated with double-layer anodizing, which is not easy to be rusted and deformed.

- The labeling mechanism adopts large sponge rollers to make the label more securely attached.

- Adopt German Siemens PLC and servo motor closed-loop control to ensure high-speed and stable labeling.

Features:

Automatic tube splitting, adopting the tube splitting mechanism, effectively eliminating the bottle splitting unsmoothness caused by the error of the bottle itself, and improving the stability;

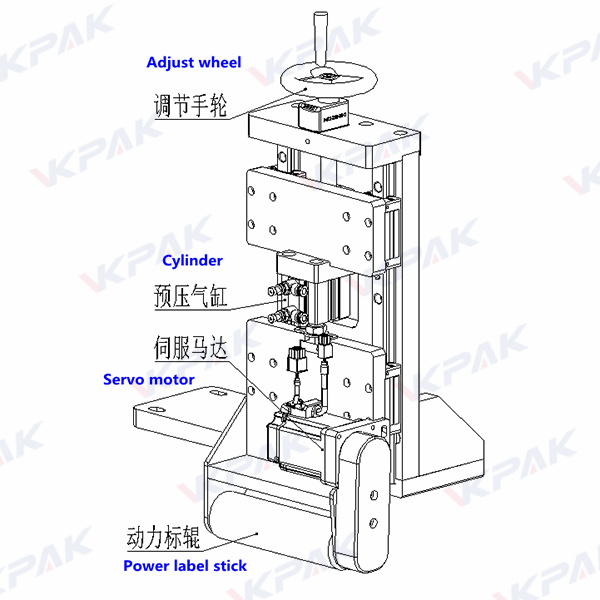

Touch screen control, human-computer interaction interface with operation teaching function, parameter modification is intuitive and clear, and various functions are simple to switch;Adopting independent patented technology and the labeling mechanism design to ensure labeling without warped edges, bubbles and wrinkles.

Intelligent control, automatic photoelectric tracking, with nothing not labeling, no label automatic correction and label automatic detection function, to avoid waste labels and leakage of labeling;

Strong and hygienic, mainly made of stainless steel and high-grade aluminum alloy, with solid quality, in line with GMP production requirements.

Machine Options:

Install ribbon coder/laser coding/Jet ink coding/TTO

Transparent label detection sensor

Add barcode detection, with or without label detection, and remaining label alarm function.

Application:

Applicable Tubes: Empty soft tubes.

Applicable Products: Hand cream, sunscreen, ointment, pigment, facial cream, toothpaste.

Applicable Industries: Cosmetic, daily chemical, medicine, chemical industries.

This automatic labeling machine is used to label self-adhesive stickers on soft tube, it can automatic feed soft tube, label stickers, and unload soft tube. It can be customized for plastic soft tube and work with automatic aluminum tube filling sealing machine to realize automated production.

Equipped with PLC touch screen control panel, the visual working data simplify the machine debugging. Rotatable control panel improves user experience. Different kinds of operation language can be customized as operation need.

Put empty soft tube into tube feeding structure, it will make tube be in order and supply them in time, with this structure, it saves working labor.

Soft tube will be rotated and stickers will be separated and sticking to the tube, the roller will press sticker during this process, ensure there is no bubble under stickers.There is an electric eye, which can be used to detecting tube and control the machine to start labeling work.

The fixing mold for sleeving soft tube can be customized according to tube sizes, changing the mold can be used for different size of tubes. This ensures the labeling accuracy.

This automatic labeling machine is equipped with PLC control panel, which can help you adjust working data easily. It can be used for labeling stickers on soft tube like hand cream, facial cleanser. This machine is widely used in food, drinks, cosmetics and daily chemical industries.