VK-T805 Semi Automatic Soft Tube Labeling Machine

The semi-automatic labeler is equipped with a rotating motor and roller for labeling different products and shapes, including empty soft tubes, flat surfaces, and round or square bottles. By changing the smoothing device, it applies labels to uneven surfaces such as a concave or curved surface. With the use of different jigs, the semi-automatic labeler will also apply labels to irregularly shaped products.

This is a multifunctional labeling machine that can label squeeze tubes. Check out the soft tube labeling machine video to see how soft tube labeling works.

Output Speed: 15 ~ 30 pieces/min

Dimension: L843mm*W759mm*H895mm

Can be based on the customer's products, change the product of the mold, to achieve this irregular product labeling. With adjustable height stroke function, different height products, do not have to repeatedly replace the rule; It is specially used for all kinds of card labeling. It has high accuracy and no bubbles on the surface of various plastic sheets. It has automatic product identification function and automatically activates different labeling heads according to different products.

Parameter

| Model | VK-T805 |

| Labeling Accuracy | ±0.5mm |

| Labeling Speed | 15-30 pieces/min |

| Applicable for product diameter | Length: 20mm-200mm, width: 20mm-180mm, Thickness: 5mm-130mm |

| Applicable Label Size | Length: 15mm-300mm, Bottom paper width: 25mm~160mm |

| Device Dimensions | 843mm*759mm*895mm |

| Applicable Power Supply | 220V/50HZ |

| Weight | 57KG |

| Applicable Label Roll lnner Diameter | 76mm |

| Applicable label Roll lnner Diameter | 280mm |

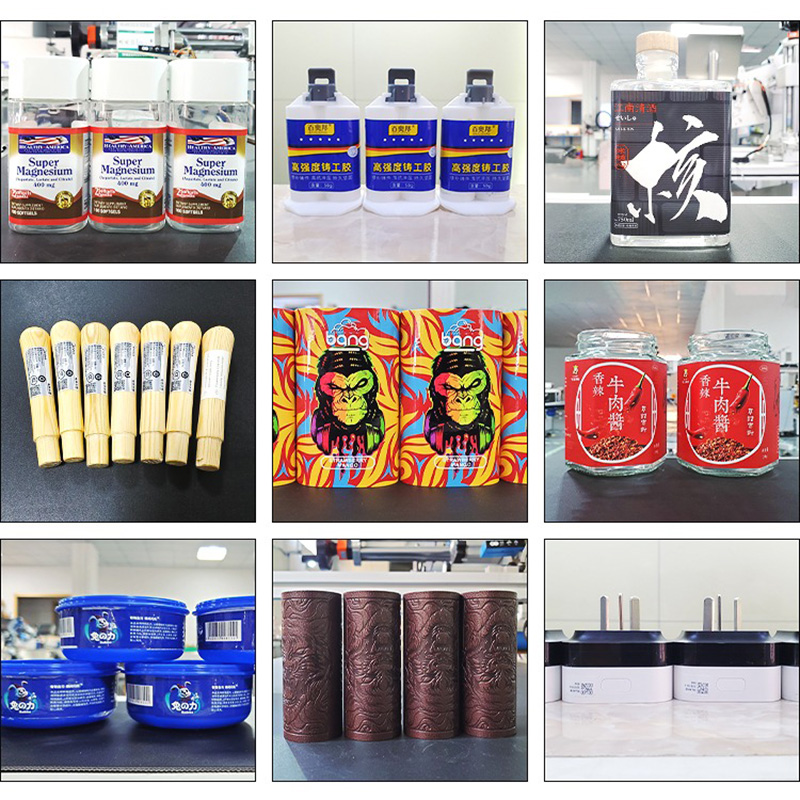

- VK-T805 is suitable for all kinds of specifications of square, round, flat and curved products labeling, such as packaging boxes, round bottles, cosmetic flat bottles, curved boards.

- VK-T805 can achieve full coverage labeling, partial accurate labeling, double labeling on the front and back of the product, double labeling on the front and side of the product, the use of double labeling function, you can adjust the distance between the two labels, widely used in packaging, electronic products, cosmetics, packaging materials industries.

- VK-T805 has additional functions to increase:configuration code printer or ink-jet printer, when labeling, print clear production batch number, production date, effective date and other information, coding and labeling will be carried out simultaneously, improve efficiency.

Working Process

Core working principle: When the sensor detects the product or receives the signal sent from the pedal, the sucker which is sucking the label falls to label and covers the product, and then goes back to the original location to suck the next label and wait for the next label signal. The whole movements of the labeling have been finished.

Procedure: Put the product -> Judge if the product arrives (controlled by the detecting equipment or manually)-> Label and cover it(the device can achieve it automatically)->Remove the labeled products.

Features:

1. Germany Sick and Italy Data logic of self-adhesive label sensor. (standard model)

2. Germany Sick and LEUZE sensor not only can use for self-adhesive label, but also can use for transparent label. (price calculated separately). Panasonic PLC, Simple operation, do not need high-quality technical workers, easy to get started.

3. Other languages available: such as: Spanish, Arabic, French. and so on.

4. The inside of machine to keep dry, use longer. it connect electric and air compressor. working pressure: 0.3-0.6 MPA

Application:

With 360 degrees rotating roll method for flat labeling, make a mold fixed the product on the machine, then 360 degree rotating and labeling to achieve high precision labeling effect. Ideal suitable for polygonal shape product for labeling, Such as: Three sides labeling Four sides shape bottle Hexagon shape bottle

Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: flat shape objects, the arc, the circumferential surface, concave, convex, or other surface attached to the label of the product; such as: Shampoo flat bottle, packaging box, caps, plastic shell and so on.

Application examples: cardboard labeling, acrylic film, large plastic film, ceramic sheet film, etc.