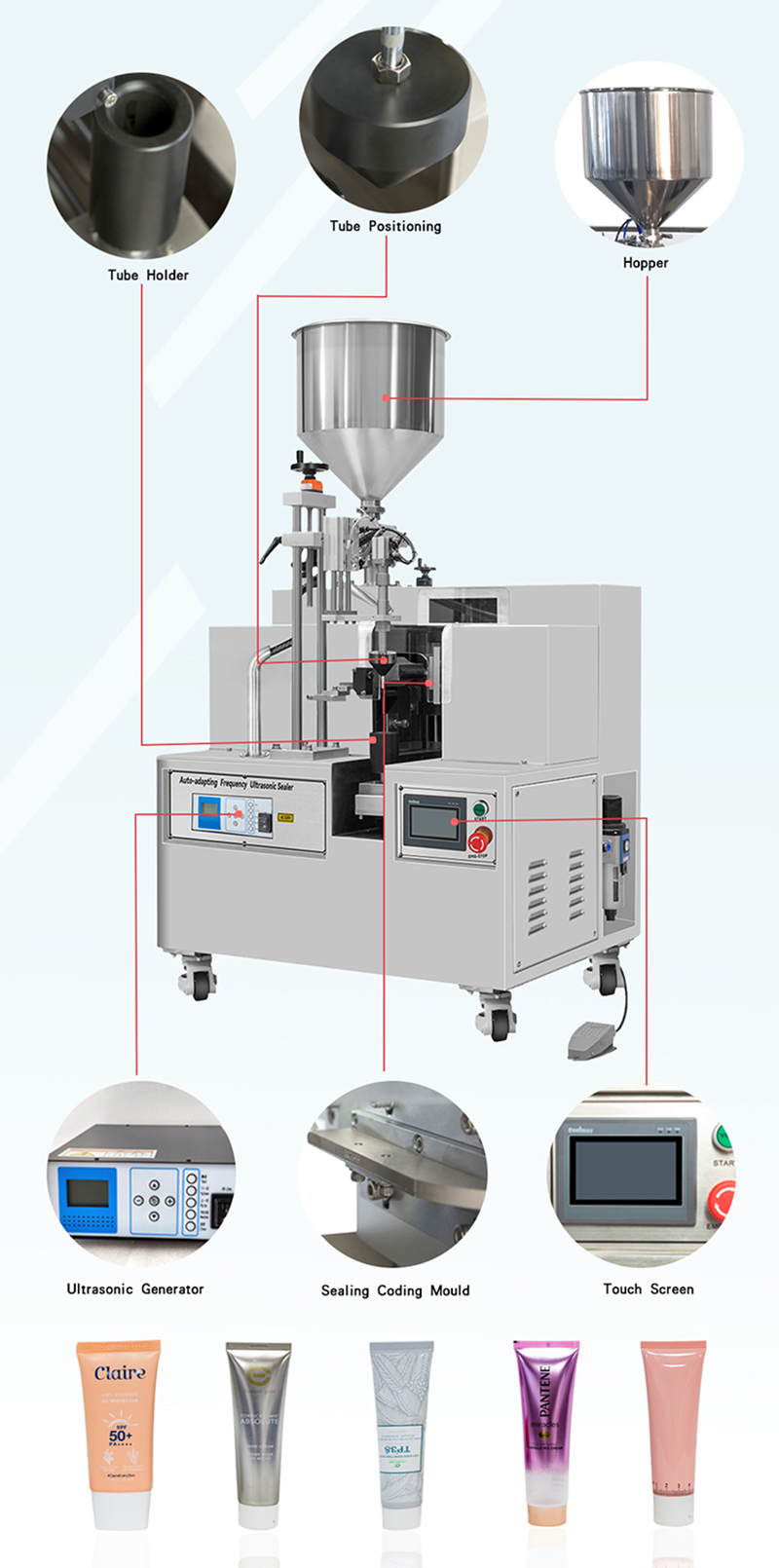

VK-TFS-002U Semi Automatic Ultrasonic Tube Filler And Sealer Machine

This semi automatic machine is suitable for filling liquid or paste into soft tubes and sealing tubes. The fixing mold of this machine can be customized according to tube size. It is also equipped with coding function which can be used to print production date on soft tube. This machine is widely used in daily chemical, cosmetics industries.

Sealing Method: Ultrasonic Sealing

Output Speed: 6-12 pieces/min

Dimension: L1000*W780*H1250mm

This machine can be customized according to customer's need. Please contact us if you need. Thank you!

Parameter

| Model | VK-TFS-002U |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | A: 6-60ml B: 10-120ml C:25-250ml D:50-500ml (could choose based on customer’s volume) |

| Filling Accuracy | ±1% |

| Capacity | 6-12pcs/min |

| Sealing Dia. | 13-50mm (Custom-made available) |

| Tube Height | 50-200mm |

| AirPressure | 0.6-0.8MPa |

| Dimension | L1000*W780*H1250mm |

| N.W | 180kgs |

- The pneumatic filling head can be used for liquid or paste like cream, toothpaste, etc. It is with anti-dripping function, ensuring the filling accuracy. The height of the filling head can be adjusted by the handle, making it suitable for tubes of different heights.

- Through the touch-screen control panel, you can set working parameters like filling speed and sealing time. Easy to operate. It is with an emergency stop button, which can avert or reduce hazards that may damage the machine.

- The tube holder is designed for positioning the tubes, enabling them to be filled and sealed well. Save labor cost. The sensor is designed for detecting the color code’s position, making the date or batch printed on the tube accurately. Intelligent and efficient.

- Adopting ultrasonic sealing method, the sealing position will be firm and beautiful. The machine will seal the tube and print production date or batch on the tube at the same time, improving work efficiency.

- With trimming function, the machine will cut the leftover material after the tube is sealed. The cutting blade is made of imported material, ensuring the edge can be cut neatly. Improve production quality.

- Oil-water Separator: It is used for filtering the water and impurities in the compressed air, ensuring the service life of air cylinder. Durable and reliable.

Working Process

Tube loading by hand

Color mark orientation and filling by piston

Ultrasonic sealing and date coding

Cutting

Features:

Compact design, with filling and sealing function all in one, very suitable for start-up manufacturers, market test, or laboratory sample proofing.

Manually feed the tube, press the start button, the machine could automatically identify the registration mark, filling, sealing with coding, end trimming.

Adopts ultrasonic sealing technology, no need warm-up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

PLC with touch screen control system, providing a friendly operation experience.

Each action could be controlled independently in touch screen, friendly for adjustment between different tubes. Workers could use one tube only to set all the positions, saving much time and material.

With Foot pedal to work for filling function alone.

"Panasonic" high sensitive sensor with a stepping motor, could track the registration mark precisely.

Equipped with filler for both liquid and cream, with filling tolerance within ±1%. Filling volume adjustable by handle wheel.

Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Machine Options:

Heating and mixing system for material hopper