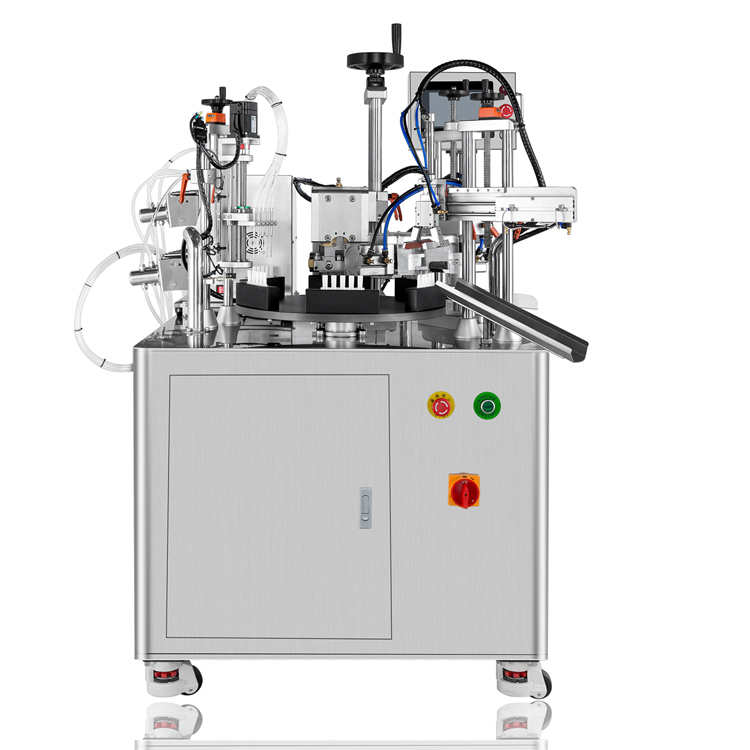

VK-TFS-005 Semi Automatic Strip Monodose Tube Filler Sealer Machine

Widely used for food, pharmaceutical, cosmetics, and chemical 5 in 1 tube filling and sealing, volume from 1-10ml.

Sealing Method: Ultrasonic Sealing

Output Speed: 10-15 pieces/min

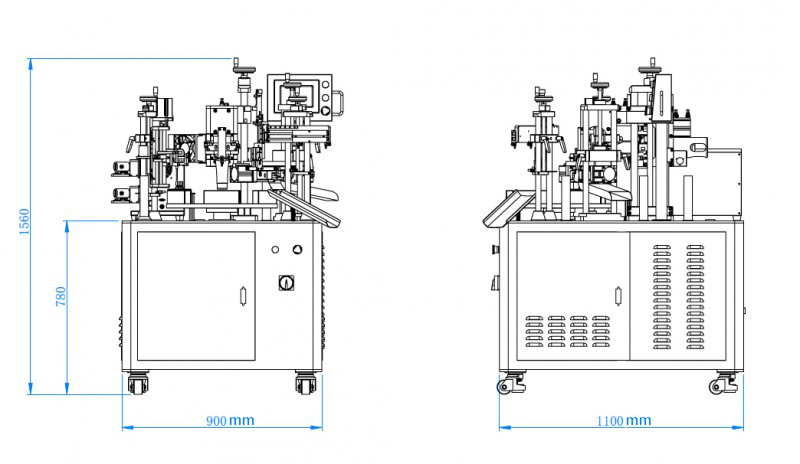

Dimension: L1300*W1010*H1550mm

This automatic machine is with function of filling and sealing, multifunctional and help you save working space. It is equipped with ceramic pump, which can fill liquid accurately. The fixing mold can be customized according to product size. This machine is widely used in cosmetics, daily chemical industries.

Parameter

| Model | VK-TFS-005 |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | 1-10ml by 5 pumps |

| Capacity | 10-15pcs/min |

| Sealing Length. | max 140mm(Custom-made available) |

| Tube Height | 50-150mm |

| AirPressure | 0.5-0.6MPa |

| Dimension | L1300*W1010*H1550mm |

| N.W | 350kgs |

- This machine is designed with ceramic pump, it can fill liquid accurately. The small filling nozzle can prevent from spreading out liquid during working, improve filling accuracy.

- The machine is equipped with high quality electric eye, which can detect soft tube and control the machine to seal and trim soft tube. Reduce production error.

- The fixing mold can be customized according to material size. This machine is also with clamping function which can clamp finished products after producing.

Working Process

5 strip tube loading one by one by hand

Auto 5 heads Filling

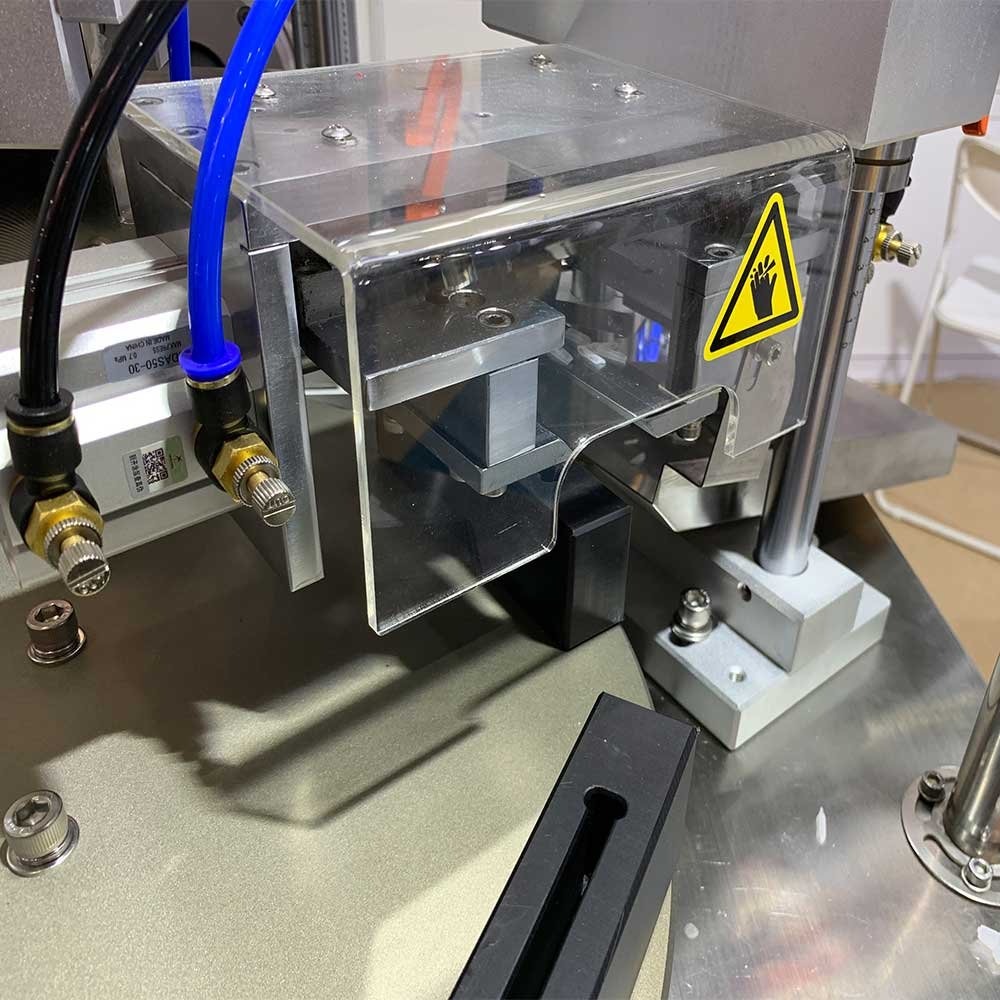

Ultrasonic sealing

Cutting

Discharging

Features:

Machine is specially designed for 5 in 1 tubes, suitable for mass production of 5 in 1 tubes.

Manually tube feeding, automatic filling, sealing, end trimming.

Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

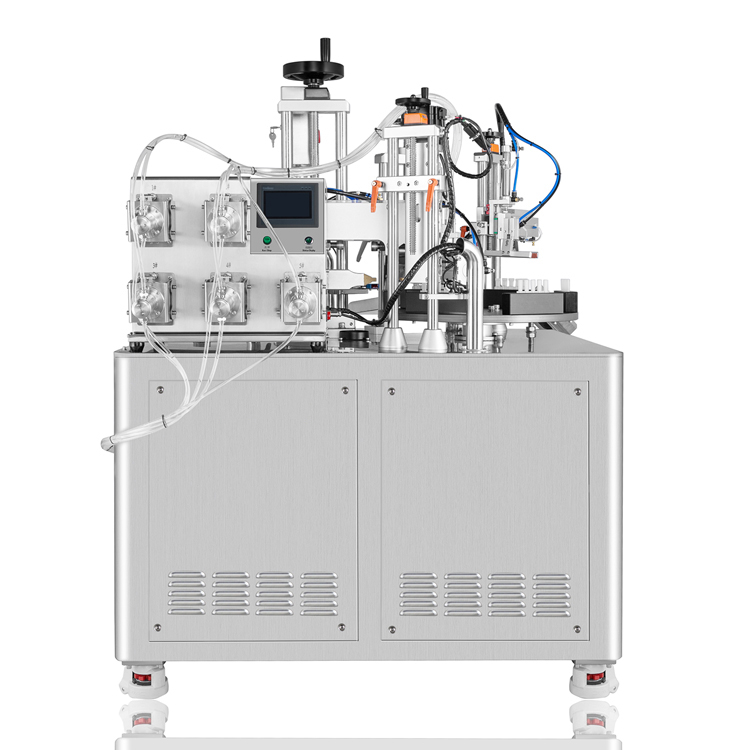

PLC with touch screen control system, providing friendly operation experience.

Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

Standard equipped with peristaltic pump filling system, high accuracy filling, and suitable for liquid filling.

No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

Cam indexing system could position precisely for six working stations.

Application:

Widely used for food, pharmaceutical, cosmetics, and chemical 5 in 1 tube filling and sealing, volume from 1-10ml.

Machine Options:

Ceramic pumps for low viscous cream and essence

Pneumatic ceramic pumps for high viscous cream