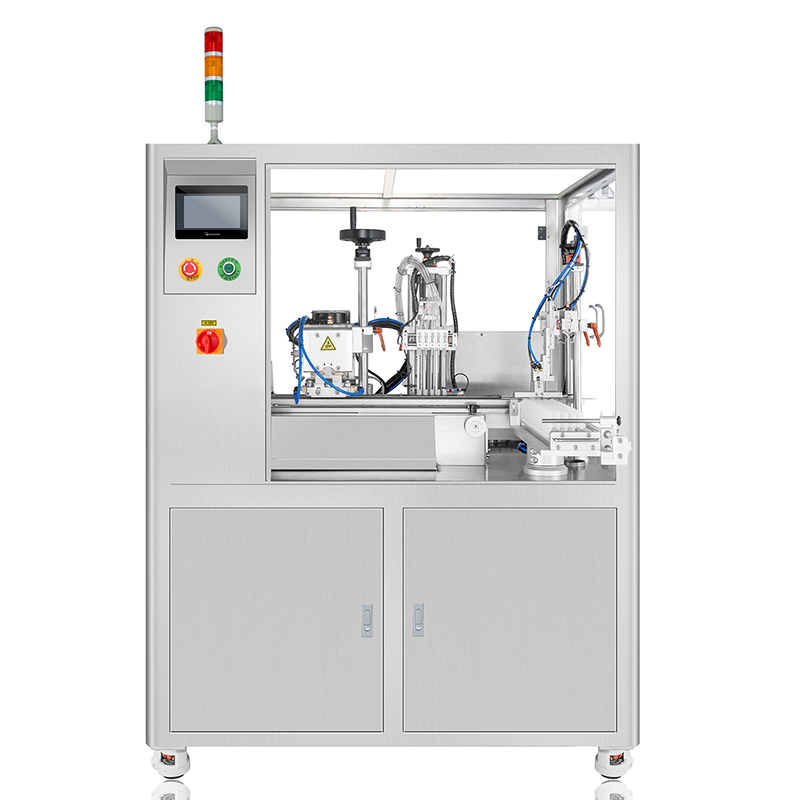

VK-TFS-005U Automatic Strip Monodose Tube Filling And Sealing Machine

A monodose strips filling and sealing machine is a piece of equipment designed to automate the process of filling individual doses of a product into monodose strips and subsequently sealing them. These machines are commonly used in industries such as cosmetics, and personal care to efficiently produce unit-dose packaging.

Sealing Method: Ultrasonic Sealing

Output Speed: 15-20 pieces/min

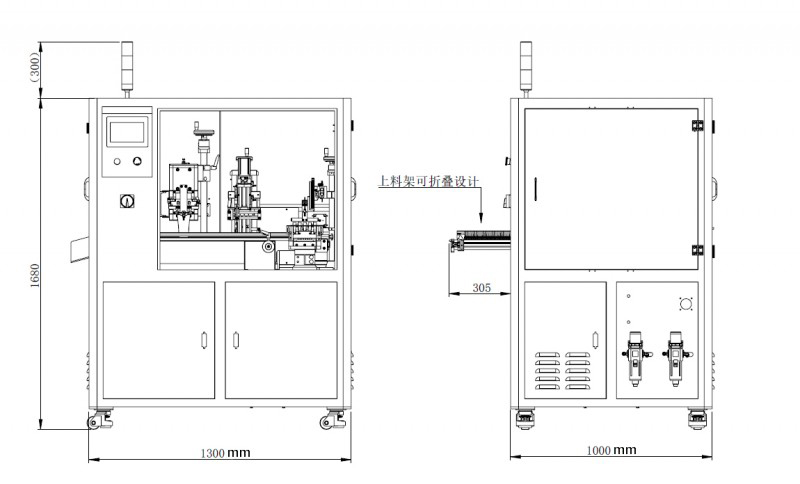

Dimension: L1300*W1300*H1950mm

Designed with precise ceramic pump, this machine suits for packing eye drops, essence.

The individual eye drops filling and sealing machine is equipped with touchscreen, making it convenient to set and adjust working parameters.

Parameter

| Model | VK-TFS-005U |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

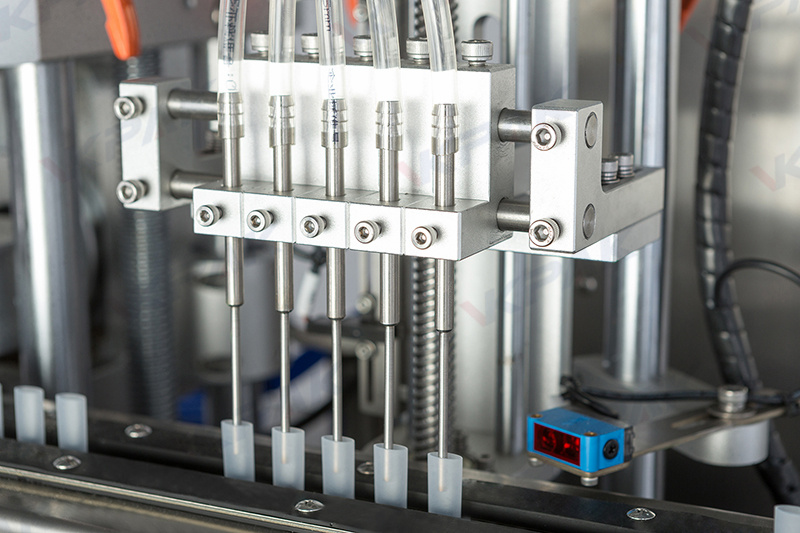

| Filling Pumps | 5 sets of electrical ceramic pumps / 5 sets of ceramic piston pumps |

| Filling Range | 0.3-10ml electrical ceramic pumps / 1-10ml ceramic piston pumps |

| Filling Accuracy | ±0.5% | Capacity | 15-20 monodose/min |

| Sealing Width | Max. 140mm |

| Tube Height | 50-120mm |

| AirPressure | 0.5-0.6MPa |

| Dimension | L1300*W1300*H1950 |

| N.W | 514kgs |

Features:

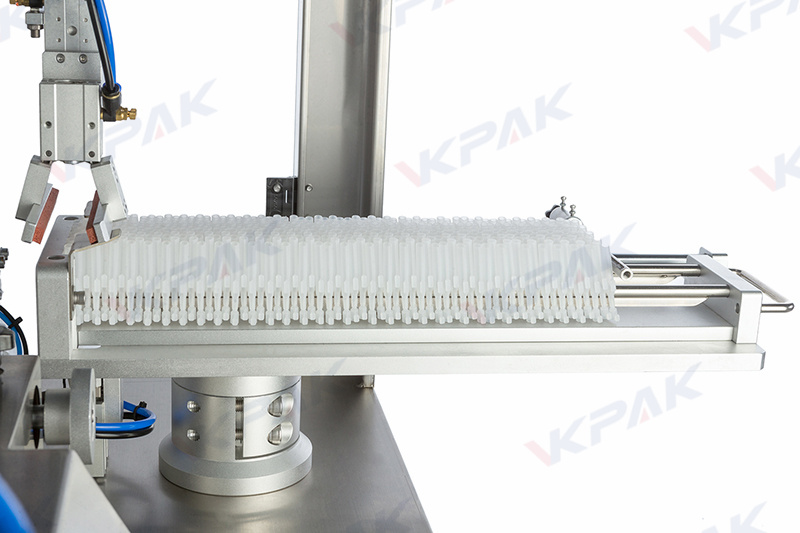

Machine is specially designed for monodose tubes, suitable for automatic filling and sealing monodose tubes.

Automatic tube pick-up and feeding, automatic accurate filling, sealing, end trimming.

Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

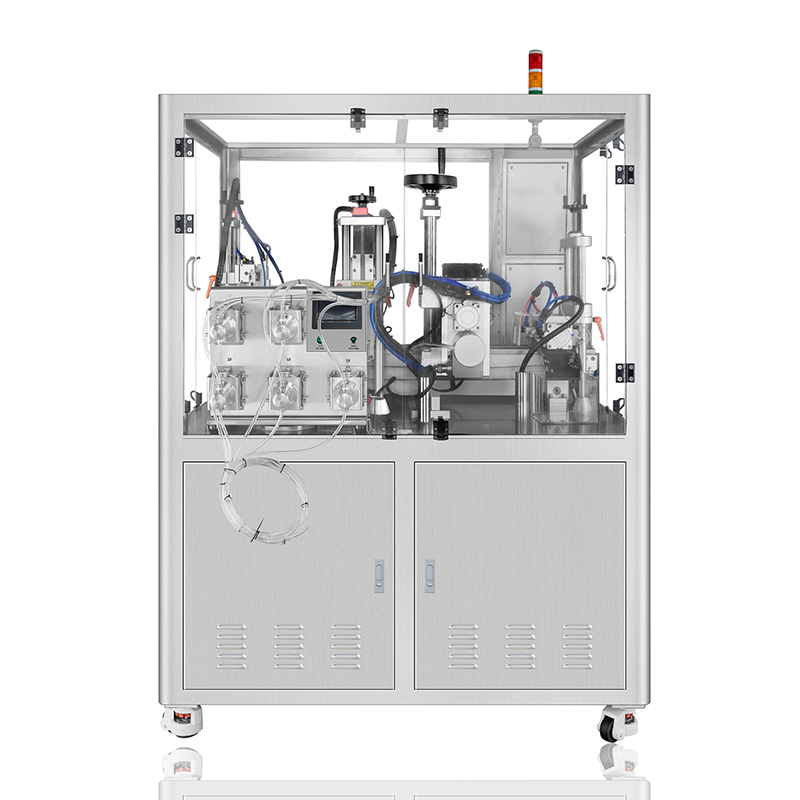

PLC with touch screen control system, providing friendly operation experience.

Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

Standard equipped with ceramic pump filling system, high accuracy filling, and could choose different filling pumps types for liquid, cream or thicker cream filling.

No tube, nofill, no tube, no seal function, reducing the machine and mould loss.

Servo motor driven chain conveyor system, more suitable for working in-line and mass production.

Application:

Widely used for food, pharmaceutical, cosmetics and chemical 5 in 1 tube filling and sealing.

Machine Options:

Custom-made filling system for cream product.