VK-TFS-006A Semi-Automatic Aluminum Tube Filler Sealer Machine

Semi-automatic aluminum tube filling and sealing machine is suitable for metal tubes . It can do automatic color mark position, filling, folding, batch coding and finished products exit in one machine.

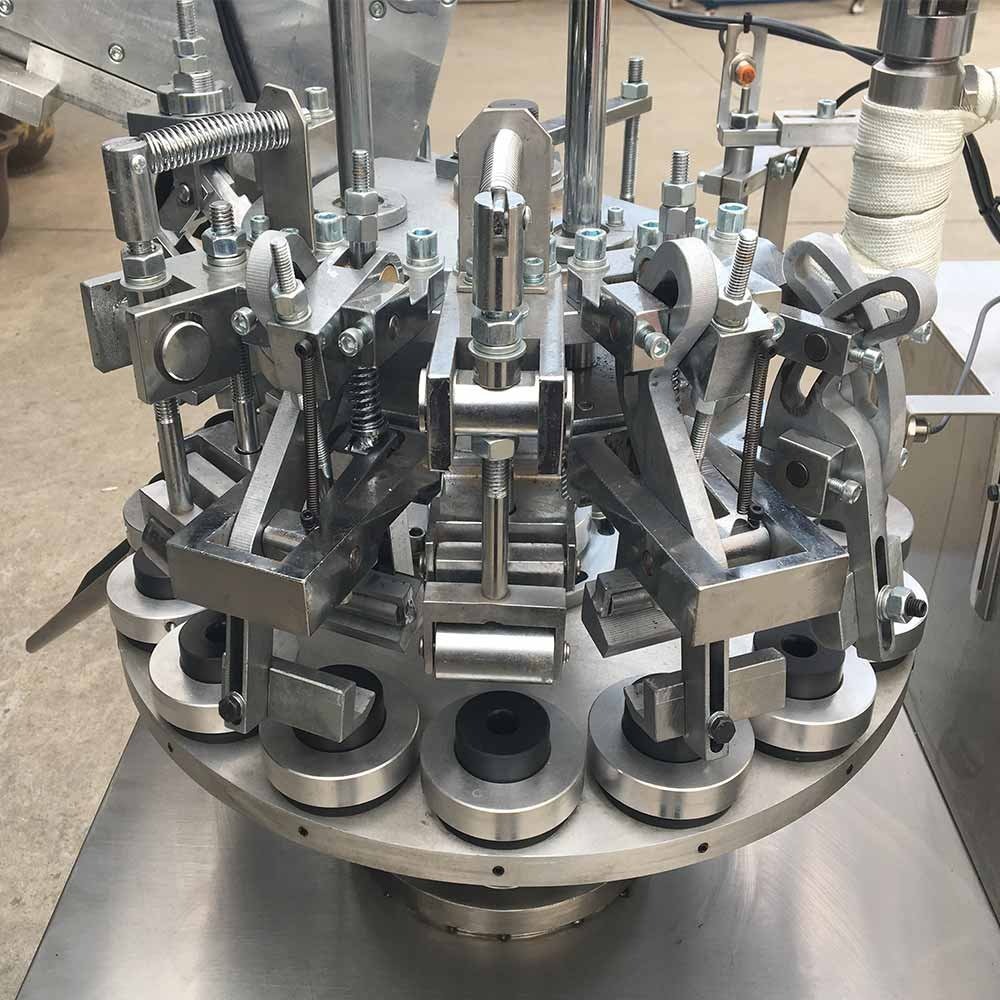

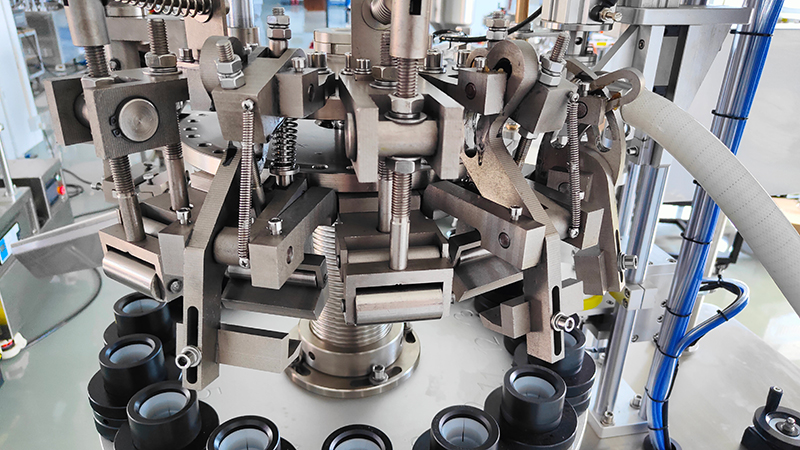

Equipped with a auto rotary table with 16 working stations, the operator manually put the aluminum tube into the tube holders. The machine then will automatically mark searching, filling, folding. It fills when there is a tube detected. No tube no filling, to avoid wrong filling. The filling is driven by air cylinder, and the filling capacity and accuracy is controlled by cylinder route.

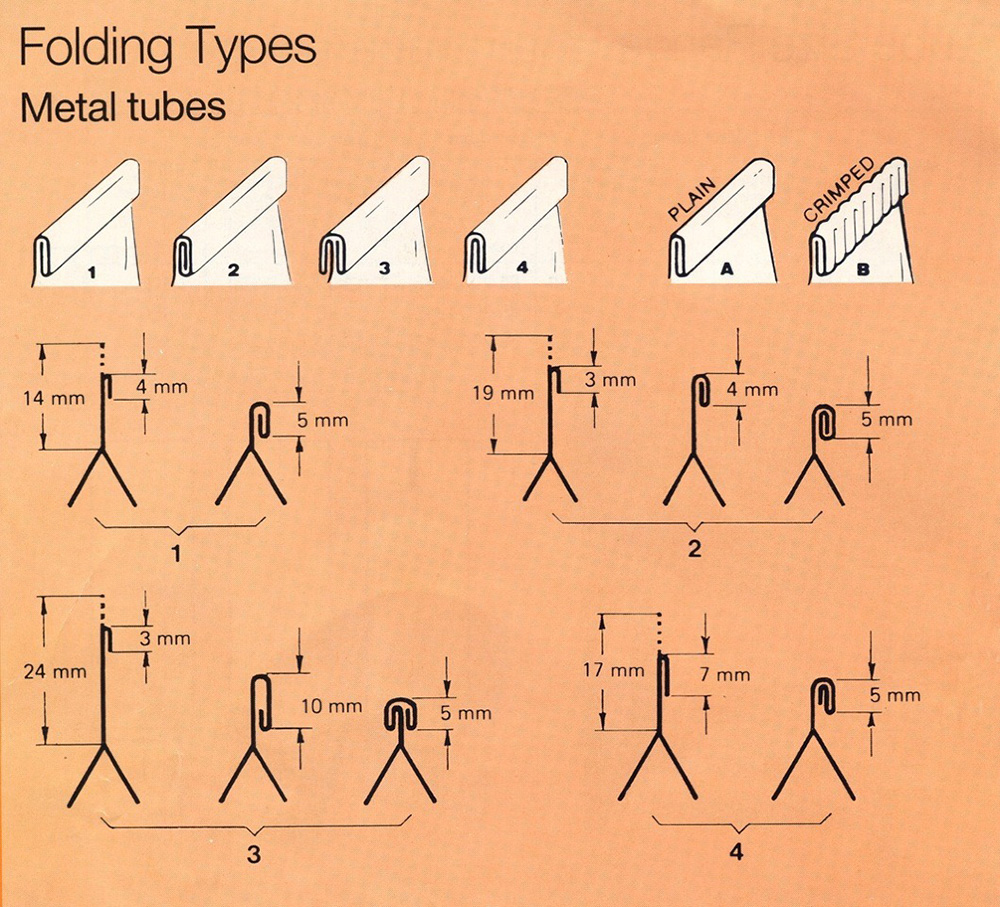

Sealing Method: Folding Sealing

Output Speed: 25-50 pieces/min

Dimension: L1500*W700*H1800mm

The aluminum tube filling sealing machine is suit for the filling and sealing of metallic aluminum tube. The machine is specially designed for clients to manufacturer instant glue, chemical or medicine. A dual four-fold sealing is reached after each turn of a station. Because it is safe and airtight, so we can ensure the excellent quality of the products. This machine adopts unlimited adjustment speed and photoelectric control. No tube no filling. As for different metal tube, we can do it just through put on the mold with different diameters.

Note that there are multiple models in this series for you to choose from!

Function:

Aluminum tube filling and sealing machine is made of high-quality stainless steel SS 304

All elements having contact with the product are made of high-quality stainless steel SS 304 or SS 316 (optional)

Touch screen and PLC control of sealing parameters and process with saving option

Filling accuracy error: < ± 1 % of volume

Single-sided coding with set of fonts included

Double fold closing(Customizable)

Output up to 25~50 tubes/minute

Works with all-aluminum tubes

Technical parameter:

| Model | VK-TFS-006A |

| Weight | 350Kg |

| Power | 220V/50Hz |

| Filling Quantity | 1-5g/5-25g/20-75g/75-250g |

| Suitable Filling Material | Aluminum and metal tube |

| Date Printed | 1-2 rows(numbers & letters) |

| Dimension | 1500*700*1800mm |

| Motor | 1.5Kw |

| Capacity | 25-50 tubes/min |

| Maximum Tube Dia. | 60 mm |

| Additional Function | Air pressured tank Diving filling function |

Working Process

Tube loading one by one by hand

Color mark orientation and tube detecting

Auto Filling, no tube no filling, 2 hoppers for 2 glues

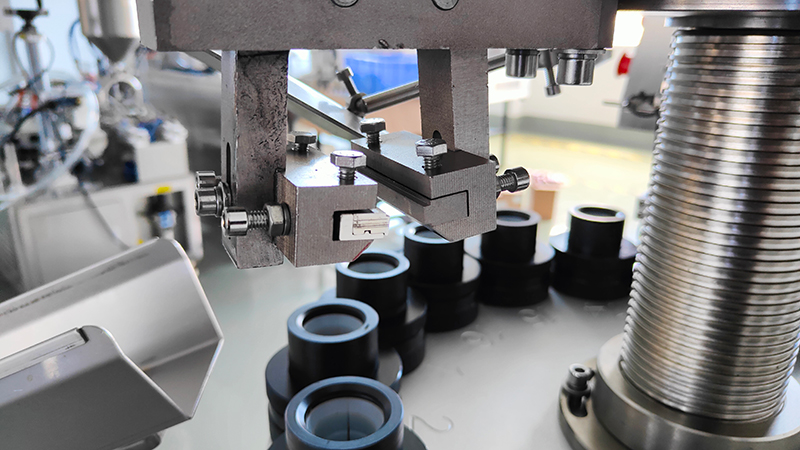

Folding (3 folds or 4 folds): flattening → crimping 90° → flattening → crimping 90° → flattening → crimping -90° → flattening with date code

Ejet out the finished product

Application:

This machine is to fill ointment material into metal tube with qnantitive volume and fold the tube end. It is widely used for pharmaceutical, cosmetic, foods, and chemical industry. for example: ointment, gooey, AB glue, epoxy glue , skin oil, hair dye, shoeshine, toothpaste, etc.

This machine features a streamlined process that begins with manually placing the tube in the star wheel station. From there, the tube moves to the turning station where the mark point at the top of the tube is sensed and rotated to the correct direction. Next, the tube moves to the filling station where it is filled using a precision piston pump. Once filled, the tube moves to the edge folding and sealing station, ensuring a secure and professional seal. Finally, the tube is discharged, ready for use.

Our monoblock is equipped with advanced PLC controls, making it easy to operate and control. Its high level of automation and precision make it the perfect choice for small and medium-sized businesses looking to enhance their packaging process.