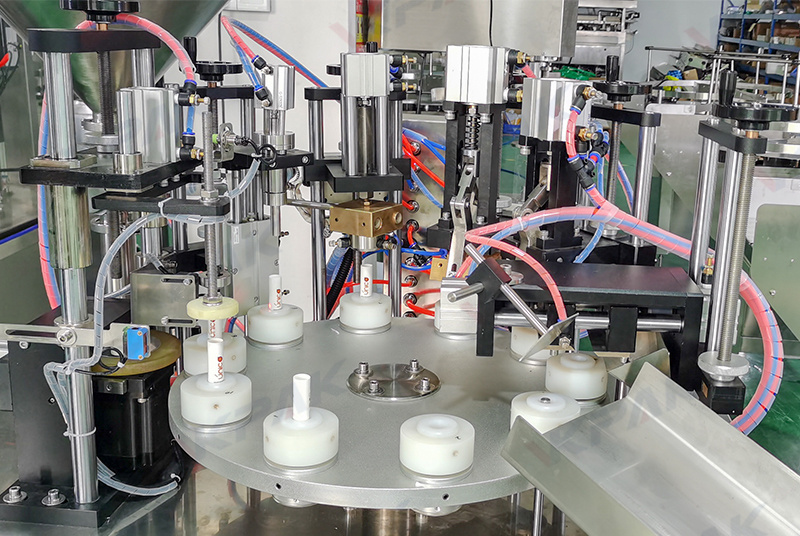

VK-TFS-006H Semi-Automatic Hot Air Sealing Filler Sealer Machine

This semi auto tube filling and sealing machine is widely used in various aluminum plastic compound soft tube, plastic soft tube. VK-TFS-006H adopts indexing device, completing a series of functions, including automatic filling, inside and outside heating, end-sealing, batch number printing, and finished product exiting. The machine is featured by accurate filling, stable and adjustable heating time, good sealing effect. The machine has ten tubes which can work automatically. The machine works stably and reliably, without noise and other pollution.

Sealing Method: Hot Air Sealing

Output Speed: 20-40 pieces/min

Dimension: L1300*W700*H1400mm

This semi auto tube filling and sealing machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc. It is applicable in various aluminum plastic compound soft tube, plastic soft tube which fill pack all kind of Such as ointment, adhesives, AB glue, neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste and else liquid, lotions and cream etc.

This machine applies the transmission principle. It uses the slot wheel dividing system to drive the conveyor table to do intermittent movement. with features of stable structure, full function, easy operation, accurate filling, stable running, as well as low noise. PLC controller or button control is depending on your request. Outer heat and inner heat is used in laminate tube, if your tube is plastic tube, inner heater can updated to LEISTER hot gun.

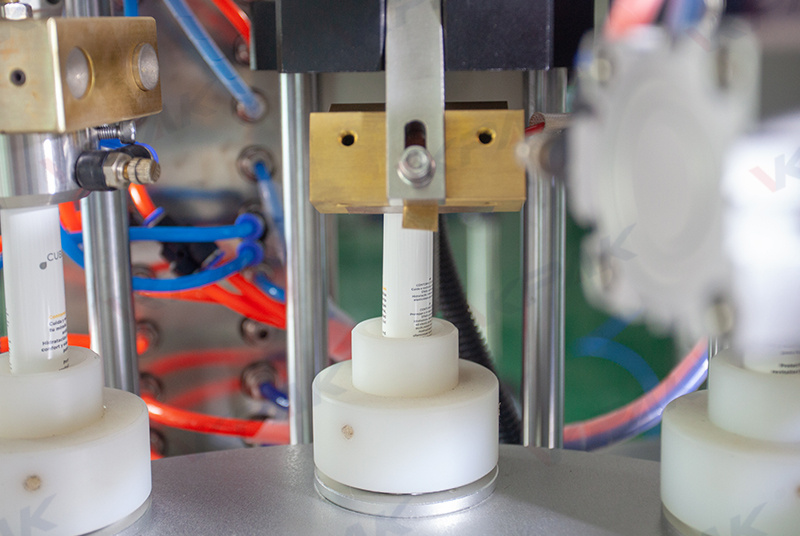

Filling measurement is accurate by the pistol plunger. Heating is stable. Sealed tail looks pretty and neat and the trimming is very even. This machine has stable performance and has no any noise and pollution during production.

Tube: plastic tube or laminate tube

Product: cream, liquid, ointment, glue, etc

Note that there are multiple models in this series for you to choose from!

Function:

The tube filling and sealing machine is made of high-quality stainless steel AISI 304

All elements having contact with the product are made of high-quality stainless steel AISI 304 and AISI 316 (optional)

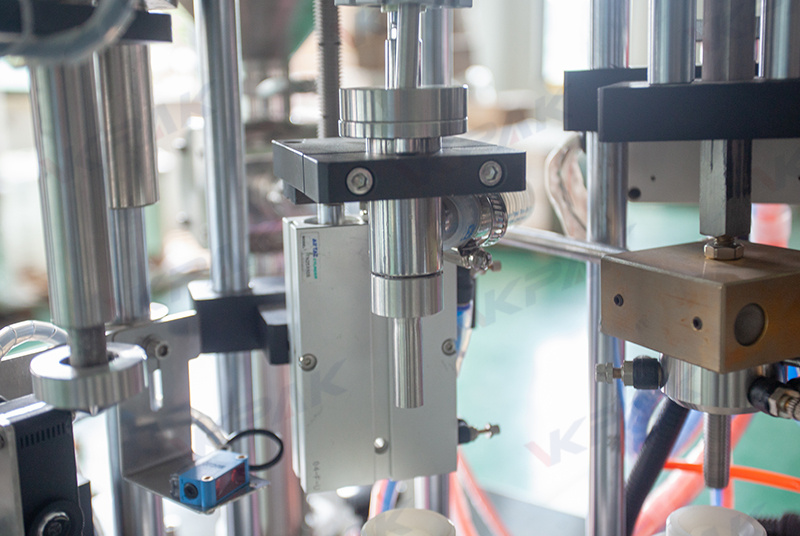

Electronic control of sealing parameters and process with saving option

Filling accuracy error: ±1 % of the volume

Hot air sealing technology

Single or dual-sided coding with set of fonts included

Output: up to 20~40 tubes/min

Works with all plastic and laminated tubes

Come with a water chiller

Technical parameter:

| Model | VK-TFS-006H |

| Weight | 250Kg |

| Power | 220V/50Hz |

| Filling Quantity | 5ml-75ml/75-250ml |

| Air Consumption | <30 m³/min |

| Compressed Air | 0.6-0.8Mpa |

| Dimension | 1300*700*1400mm |

| Motor | 4.5Kw |

| Capacity | 20-40 tubes/min |

| Tube size | 35mm |

| Quantity Error | <1% |

Working Process

Tube loading by hand

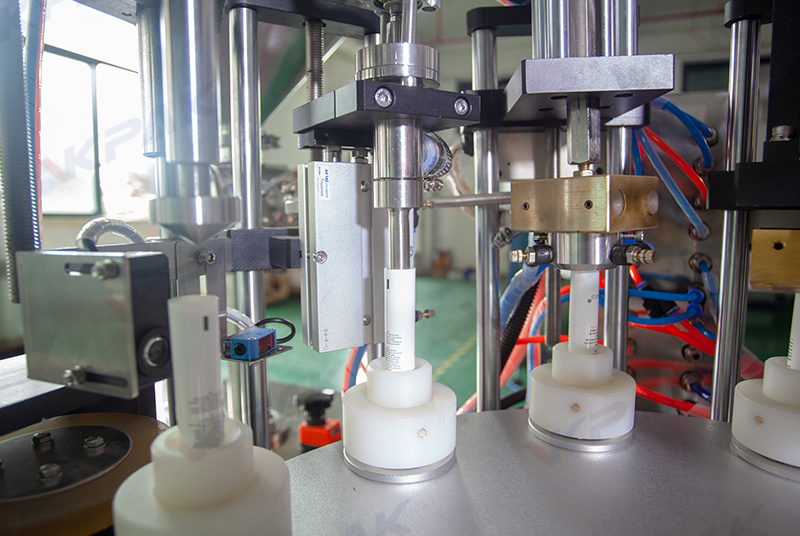

Color mark orientation and tube detecting

Auto Filling

Hot air heating

Sealing and date coding

Cutting

Ejet out the finished product

Application:

The VK-TFS-006H semi-automatic tube filling and sealing machine is used for the packing of cosmetics, pharmaceuticals, chemicals, and food products into plastic/laminated tubes. The tube filling device is designed to handle large and medium-size batches / production lots / jobs.

- This machine is designed specially for plastic soft tube filling and sealing. (load tubes by hand)

- It works for both liquid and sticky products like cream, honey, tooth paste etc

- It is applicable to all kinds of plastic and plastic combined soft tube, with coder for date and so on.

- Same machine can work for both plastic and plastic aluminium composite

All the parts of the machine that contact materials are made of high-quality stainless steel. For parts that need to be cleaned, they are easy to disassemble and wash. When some materials need to be heated and kept warm, a heating and temperature-maintaining device can be installed on the outside of the barrel.

The machine is driven by a motor as the main power, goes through a worm gear reducer and performs variable frequency speed regulation. Through a set of sheaves, the gears run intermittently, so that the 10 fixtures mounted on the turntable are equiangularly moved. (Isometric movement: the stroke of each fixture is the same when it runs to the next position) After the tube is manually loaded, filling process resumes. The whole filling system is driven by cylinders and is equipped with a metering adjustment screw, which can be adjusted within a certain range, and the accuracy can reach ±1%. In order to prevent the material from dripping, the filling nozzle of the machine is in the form of insertion, and the advance and retreat movement is driven by the lifting cylinder.