VK-TFS-006U Semi-Automatic Ultrasonic Filler Sealer Machine

The VK-TFS-006U is linked with ultrasonic sealing, the heat required for melting is only generated inside the thermoplastic sealing layer. For localized conversion of vibrations to friction heat, the anvil or sonotrode profiles are mostly linear and include radii or small plateaus. These profiles ensure focusing of the energy input and therefore short sealing times between 100 and 200 milliseconds. With ultrasonic sealing heat is generated at the inside of the film, not by heat input from the outside as is the case with heat sealing, for example. The tools (sonotrode and anvil) that come into direct contact with the packaging material, remain cold during the entire weld process. The support layer remains almost cold and upon termination of energy input, the heat dissipates faster to the outside due to the temperature difference between the support layer and the sealing layer so that the hot-tack resistance is significantly higher.

Sealing Method: Ultrasonic Sealing

Output Speed: 18-22 tubes/min

Dimension: L1300*W900*H1550

This machine integrates functions of filling paste, sealing and trimming plastic tubes automatically. Driven by piston pump, it is applicable for packing toothpaste, body butter, ketchup, etc. The plastic tube filling and sealing machine can be customized to suit for your need.

Parameter

| Model | VK-TFS-006U |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | A:6-60ml B:10-120ml C:25-250ml D:50-500ml |

| Filling Accuracy | 1% |

| Capacity | 18-22 tubes/min |

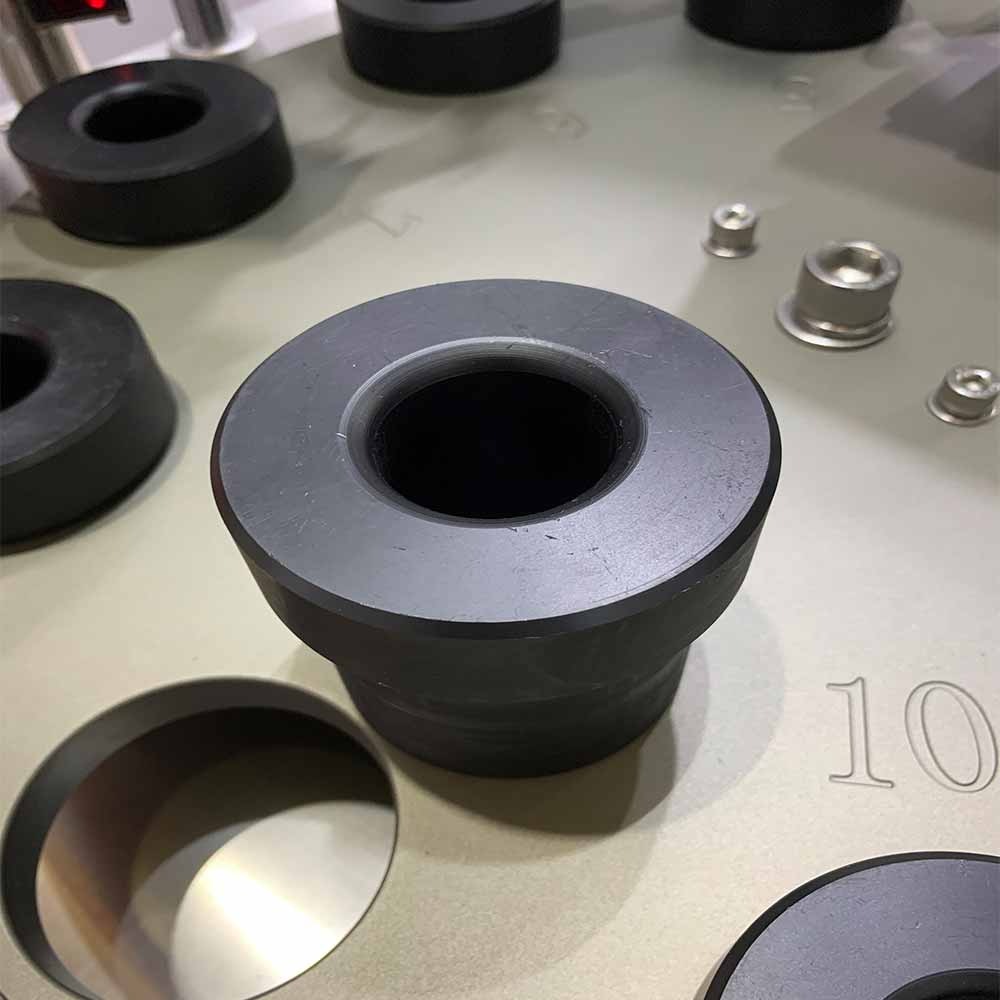

| Sealing Dia. | 10-50mm (Custom-made available) |

| Tube Height | 70-210mm |

| AirPressure | 0.6MPa |

| Air Consumption | 0.35m3/min |

| Dimension | L1300*W900*H1550 |

| N.W | 350kgs |

Working Process

Manually tube loading one by one

Color mark orientation and tube detecting

Auto Filling

Ultrasonic sealing and date coding

Cutting

Discharging

Product Details

- Designed with PLC panel, it is convenient to set and adjust working parameters like sealing time. The language of panel can be customized as your need.

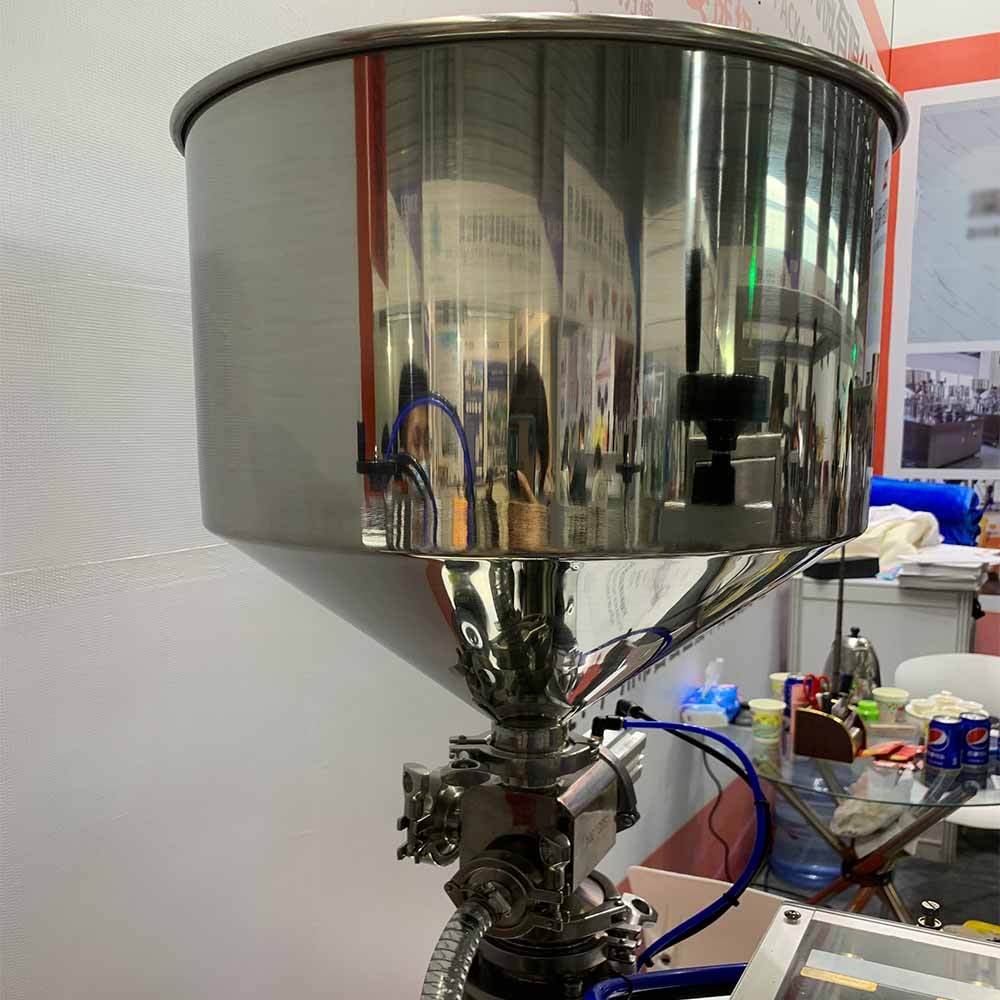

- Equipped with piston pump(The pump can be changed according to the material), this machine can fill thick paste accurately, which suits for filling toothpaste, hand cream. The filling range and quantity of nozzles can be customized as your need.

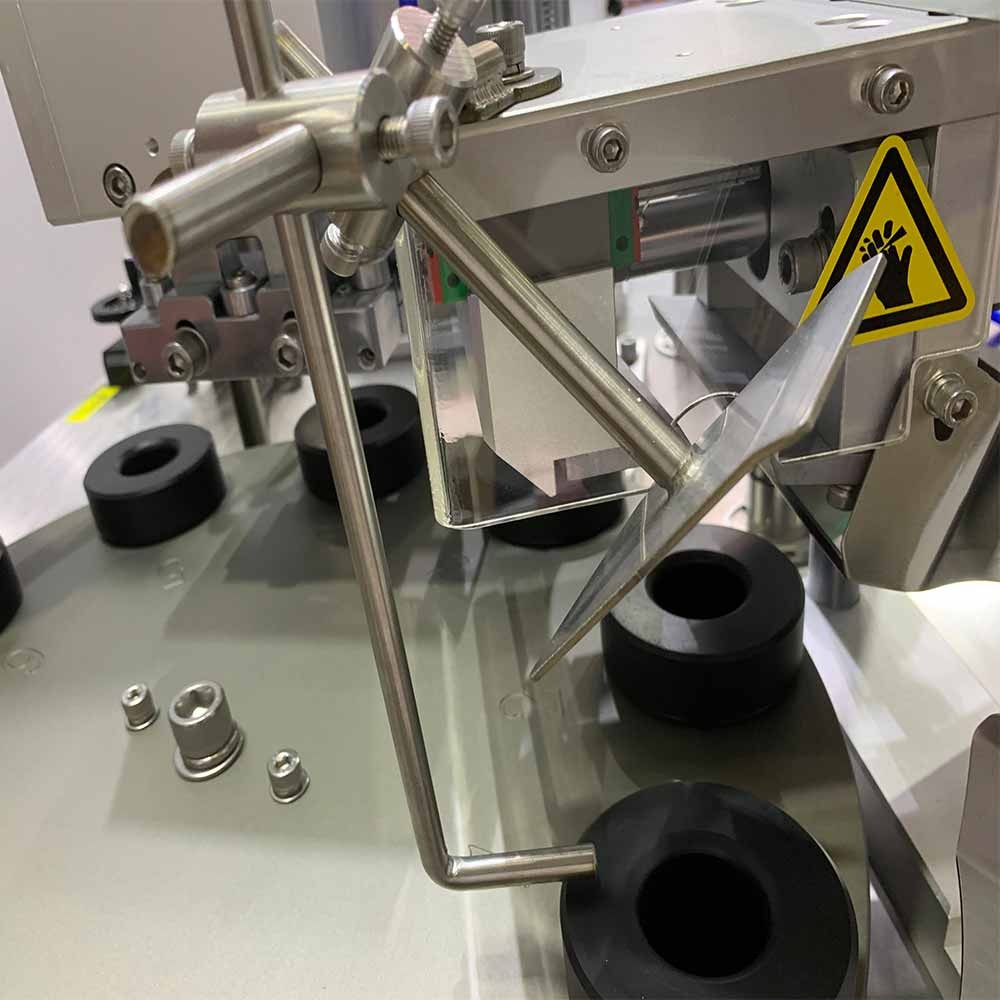

- Adopting the method of ultrasonic sealing, this machine can seal sauce tubes firmly. It can be equipped with letter molds, which can print production date automatically.

- This structure is designed for trimming tubes after sealing, ensuring good production quality. It can be customized according to tube size.

- The rotary plate is designed for fixing and transporting sauce tubes during production, helping to improve efficiency. Fixing molds can be customized to suit for your products.

Features:

Manually tube feeding, automatic registration mark identifying, filling, sealing with coding, end trimming, tube out feeding.

Cam indexing system could position precisely for ten working stations.

Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

No tube, nofill, no tube, no seal function, reducing the machine and mould loss.

Adopts anti-dripping filling nozzle.

Machine Options:

Auto refill pump

Heating and mixing system for material hopper

Air blow system for high viscous and sticky material

Safety door

316L stainless steel contact parts