VK-TFS-006UDH Semi Automatic Double Head Tube Filler Sealer Machine

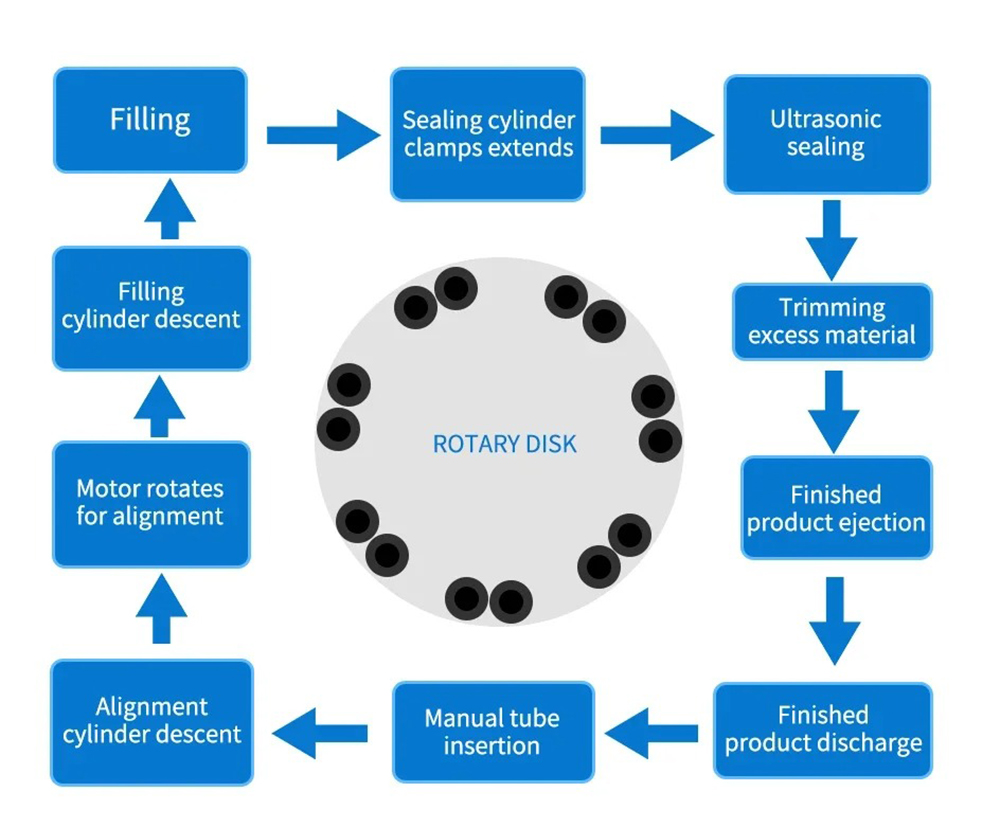

The semi-automatic ultrasonic sealing machine is a high-quality, high-performance packaging machine. The machine features manual tube feeding, automatic color mark detection, automatic sealing, automatic cutting, and automatic output of finished products, among other functions. It utilizes PLC programming, an advanced touch-screen human-machine interface, and photoelectric automatic positioning and tracking, making the overall operation simpler and more efficient. This machine helps businesses improve production efficiency, reduce labor intensity, and is the preferred equipment for upgrading packaging standards.

Sealing Method: Ultrasonic Sealing

Output Speed: 40-50 pieces/min

Dimension: L1070*W830*H1310

- Equipped with PLC control panel, working data can be set more conveniently. This is can help to watch machine working status in real time. Customizable interface simplifies machine operation.

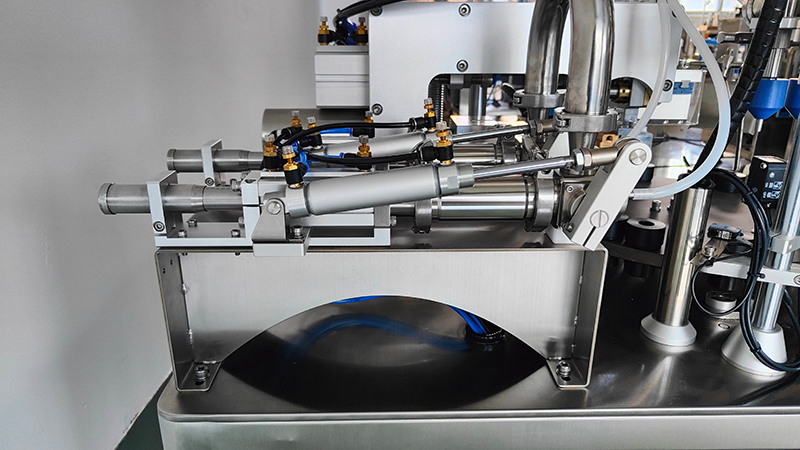

- Equipped with double filling nozzles, this can improve working capacity effiectively. The working height of filling nozzle can be adjusted according to operation need. Filling work is controlled by ceramic pump, it has high filling accuracy.

- Ultrasonic controlled tube sealing, this can improves sealing quality. Sealing temperature can be adjusted according to tube material. There is a sensor at each working station, it realizes automated work.

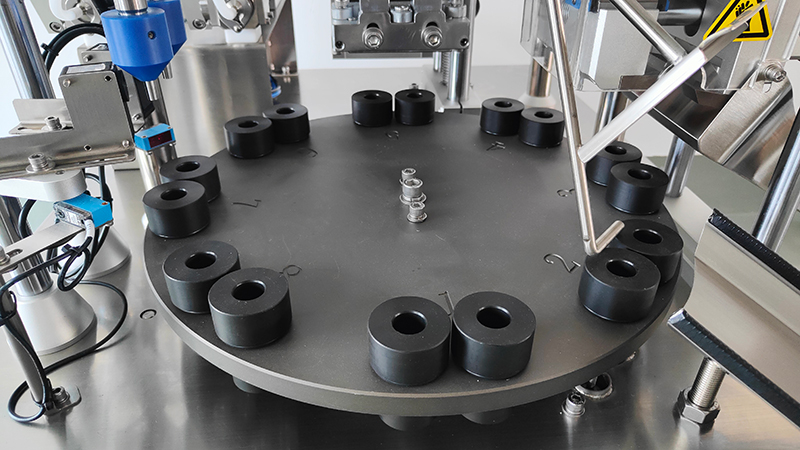

- Rotary table conveyed tube to each working station,it prevent soft tubes from falling down during conveying. Bottom fixing molds are customized according to tube size.The discharge port is equipped with a shielding plate to improve the working quality of outputting finished products.

Parameter

| Model | VK-TFS-006UDH |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | 1-12ml,6-30ml,10-60ml |

| Pump | Ceramic pump (99.7%, stainless steel 304) |

| Filling Accuracy | ±0.25-0.5ml (depending on material condition) |

| Capacity | 40-50pcs/min |

| Sealing Dia. | 13-19mm (Custom-made available) |

| Tube Height | 70-210mm |

| AirPressure | 0.5MPa |

| Dimension | L1070*W830*H1310 |

| N.W | 320kgs |

Working Process

Product Details

- The VK-TFS-006UDH tube filling sealing machine is a monoblock system that automates the entire packaging process for soft tubes. Equipped with ultrasonic controlled sealing technology, this machine ensures precise and high-quality packaging. It is specifically designed for filling and sealing products like hand cream, lip gloss, and facial cleansers.

- This innovative machine combines speed, accuracy, and reliability to optimize production efficiency. With its rotary table design, it can fill and seal multiple tubes simultaneously, reducing processing time and increasing output. The ultrasonic sealing technology guarantees a secure and consistent seal, preventing any leakage or contamination.

- The VK-TFS-006UDH is highly versatile, accommodating various paste-based products. Whether it’s thick creams, viscous gels, or sticky ointments, this machine can handle a wide range of consistencies. Its adjustable settings allow for precise control over filling quantities, ensuring consistent product dosing and reducing waste.

- Designed with ease of use in mind, the VK-TFS-006UDH features a user-friendly interface and intuitive controls. Operators can easily set parameters, monitor the filling and sealing process, and make adjustments as needed. The machine’s robust construction and ergonomic design contribute to its longevity and operational efficiency.

- By utilizing ultrasonic sealing, this machine ensures that each tube is hermetically sealed, maintaining product freshness and extending shelf life. The accuracy of the filling process guarantees consistent product volume, enhancing customer satisfaction and brand reputation.

- The VK-TFS-006UDH offers a comprehensive solution for efficient and reliable packaging of paste-based products. Its advanced features, versatility, and user-friendly operation make it a valuable asset for businesses in various industries. By investing in this state-of-the-art machine, companies can optimize their production processes, improve packaging quality, and ultimately enhance customer satisfaction.

Features:

State-of-the-Art Monoblock Filling and Sealing

The VK-TFS-006UDH is a monoblock machine that can automatically fill paste into soft tubes and seal them on a single rotary table. This seamless integration of filling and sealing processes not only saves time but also enhances the overall efficiency of the production line.

Precision Ultrasonic Sealing

Equipped with an ultrasonic controlled sealing structure, the machine ensures that each tube is sealed with the highest quality and accuracy. This advanced technology guarantees that the contents are securely packaged, maintaining their integrity and extending shelf life.

Ideal for a Variety of Cosmetic Products

Whether it’s hand cream, lip gloss, or facial cleanser, the VK-TFS-006UDH is versatile enough to handle a wide range of cosmetic products. Its precision filling and sealing capabilities make it an indispensable part of any cosmetic manufacturing operation.

Boosting Productivity with Dual Nozzle Design

The machine’s dual nozzle design allows for simultaneous filling of two tubes, effectively doubling the production capacity. This feature is particularly beneficial for businesses looking to scale up their operations without compromising on quality.

In conclusion, the VK-TFS-006UDH 2 heads tube filling ultrasonic sealing machine is a game-changer in the cosmetic packaging industry. It embodies VKPAK’s dedication to providing cutting-edge machinery that enhances productivity and ensures the highest standards of packaging quality.