VK-TFS-009A Automatic Metal Tube Filling And Crimping Machine

Automatic tube filling machines are designed and engineered to produce outstanding quality and precision tube filling and sealing of aluminum tubes or metal tubes with the output of up to 80 tubes per minute. It is widely used in cosmetics, pharmaceuticals, chemicals and foodstuffs industries.

Our aluminum tube filling machine can handle viscous, semi-viscous and liquid products including paste, ointment, lotion, topical, moisturizer, conditioner, cosmetics, toothpaste, shaving cream, and other chemical and foodstuff products.

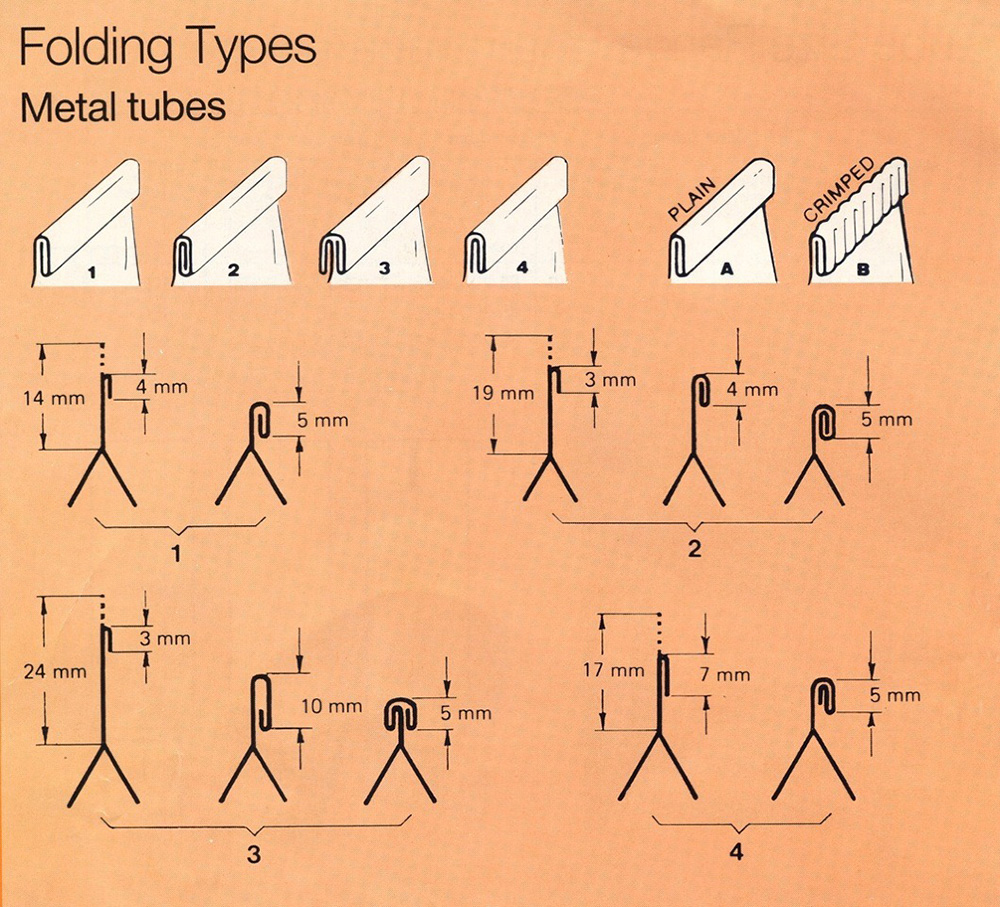

Sealing Method: Folding Sealing

Output Speed: 30-60 pieces/min

Dimension: L2500*W1200*H2400mm

With easy and quick adjustment, it is suitable for filling and crimping multiple kinds of soft tubes. The part contacting materials is made of 316L stainless steel, clean, sanitary and conforming to CMP for medicine manufacture.

Function:

The touch screen control panel makes working data visual, this is more convenient to debug machine and watch the working status in real time.Different kinds of operation language can be customized as needed.

The tube feeding structure can ensure the aluminium tube will be place into tube holder smoothly and orderly, it reduces working error and labor.

Equipped with piston pump and pneumatic filling nozzles, this is more powerful when filling thicker liquid and paste.

The number of sealing structure can be customized according to production need.The folding width at the sealing can be adjusted as needed.Extra date coding machine can be equipped with to print batch number or production date.

Technical parameter:

| Model | VK-TFS-009A |

| Weight | About 900Kg |

| Power | 380V/220V/50Hz |

| Filling Volume | 6-75ml/20-150ml/50-300ml (according to production need) |

| Suitable Filling Material | Aluminum and metal tube |

| Tube Length | 60-220mm(Can be customized) |

| Dimension | 2500*1200*2400mm |

| Filling Accuracy | ≤±1% |

| Capacity | 30-60 tubes/min |

| Maximum Tube Dia. | Φ10-50mm |

| Additional Function | Air pressured tank Diving filling function |

Working Process

Metal tube loading one by one automatic

Color mark orientation and tube detecting

Auto Filling, no tube no filling

Folding (3 folds or 4 folds): flattening → crimping 90° → flattening → crimping 90° → flattening → crimping -90° → flattening with date code

Ejet out the finished product

Features:

Compact Design

Driving Parts Fully-closed

Pneumatic Tube Washing & Feeding

Intelligent Temperature Control and Cooling System

Easy to Operate and Adjust

316L Stainless Steel Contact Parts to meet GMP Standard

Safety Interlock Shutdown when Door is Open

Overload Protection Provided

Automated Working process from Tube Loading to Finished Products Output

Automatic Orientation Effected by Photoelectric Induction

Application:

Automatic aluminum tube filling and folding machine is widely used in pharmaceutical, food, daily cosmetic and chemical industries. It is used for aluminum tube.

The aluminum tube filling folding machine is suit for the filling and sealing of metallic aluminum tube. The machine is specially designed for clients to manufacturer instant glue, chemical or medicine. A dual four-fold sealing is reached after each turn of a station. Because it is safe and airtight, so we can ensure the excellent quality of the products. This machine adopts unlimited adjustment speed and photoelectric control. No tube no filling. As for different metal tube, we can do it just through put on the mold with different diameters.

This filling and sealing machine are widely used in pharmaceutical, cosmetic, food and chemical industries etc., it is applicable in various aluminum tube, which fill pack all kind of Such as ointment, adhesives, AB glue, neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste, lotions and cream etc.

Tube feeding auto, color marking identification, filling, folding, code printing, finished tube ejection are finished one by one through an automatic control system.

Designed with PLC panel, it is more convenient to control and debug the machine. Language of panel can be customized as your need.

Driven by piston pump, it is suitable for filling thick liquid or paste like glue. Filling range of the pump can be customized.

The aluminium tube filling and sealing machine can be equipped with letter molds, which can print production date on tubes. Please contact us if you need it.