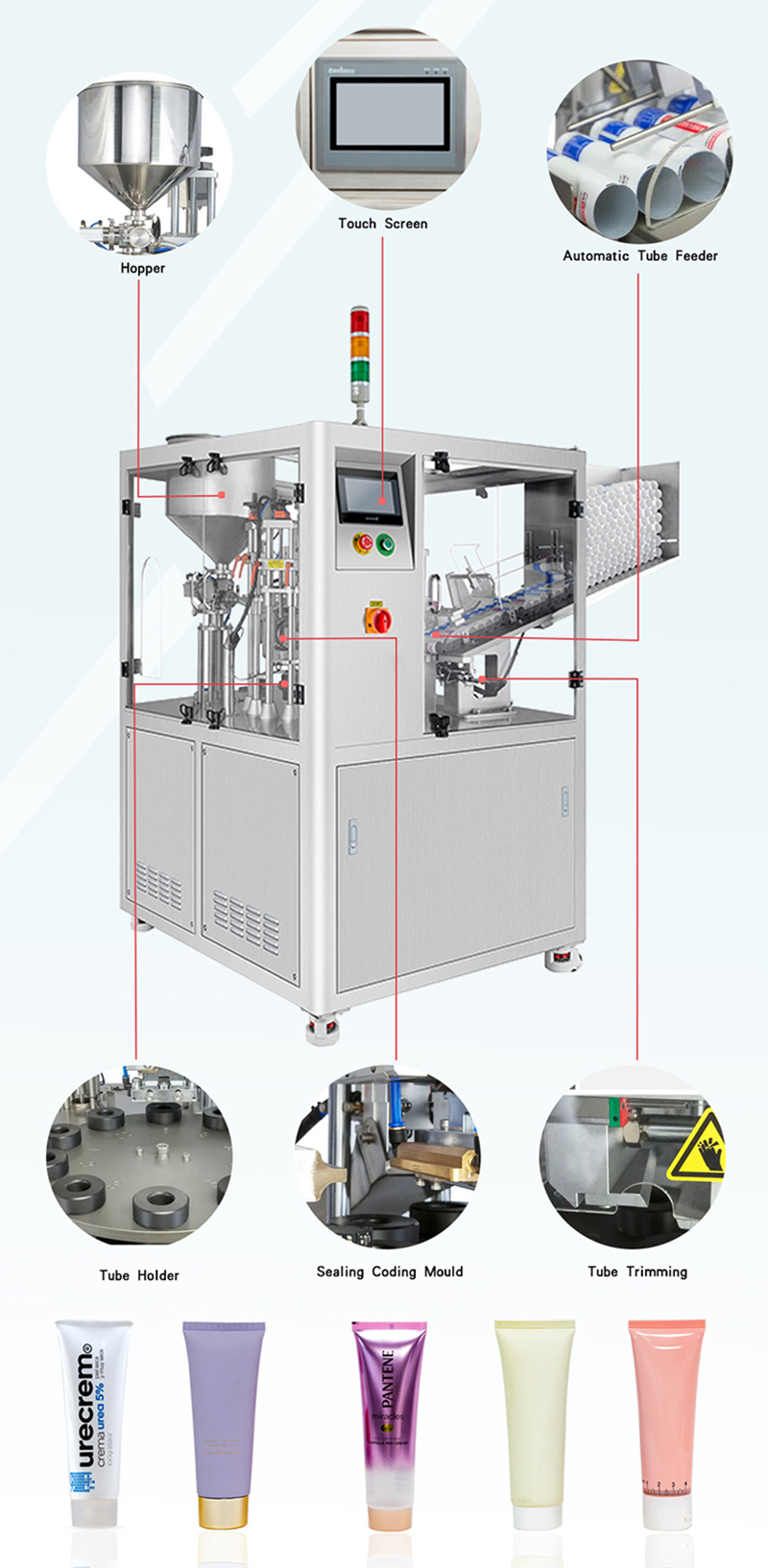

VK-TFS-009U Automatic Ultrasonic Filling And Sealing Machine

Ultrasonic tube filling and sealing machine uses intelligent digital ultrasonic technology to enable molecules on the surface area of the tubes to be fused together by ultrasonic friction. Intelligent digital ultrasonic welding avoids the disadvantages that weak welding causes due to foreign matter adhering to the walls.

TFS-009U fully automatic ultrasonic tube filling and sealing machine is the perfect choice for pharmaceutical and cosmetic cream or other cream products.

Sealing Method: Ultrasonic Sealing

Output Speed: 20-28 pieces/min

Dimension: L1630*W1300*H1580

Compared with hot air sealing, the ultrasonic tube sealing has the following advantages:

Fast sealing, save time

Sealing is nice looking, different shape sealing

Lower power consumption, energy saving

Parameter

| Model | VK-TFS-009U |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Filling Range | A:6-60ml B:10-120ml C:25-250ml D:50-500ml |

| Filling Accuracy | 1% |

| Capacity | 20-28pcs/min |

| Sealing Dia. | 16-50mm (Custom-made available) |

| Tube Height | 50-250mm |

| AirPressure | 0.6-0.8MPa |

| Air Consumption | 0.38m3/min |

| Dimension | L1630*W1300*H1580 |

| N.W | 550kgs |

- Through the PLC operation panel,you can set working parameters like filling speed and sealing time. The visualized data makes it easier to control the machine. And the language of the panel can be customized according to customers’need.

- With anti-dripping function, it can fill liquid or paste more accurately. The position of the filling head can be adjusted by the rotary handle, making it suitable for tubes of different heights. Easy and convenient.

- When the sensor detects the tube, the machine will seal tube and print date or batch on the tube at the same time Intelligent and efficient. Adopting ultrasonic sealing method, the sealing position will be firm and beautiful.

- The tube feeder is used for making the tubes in order and feeding them automatically, saving labor cost and improving work efficiency.

- Tube holder is designed for positioning the tubes, enabling them to be filled and sealed well. Save labor cost and improve work efficiency. The molds can be customized according to tubes’size.

- Larger air cylinder, it can ensures the machine has larger power and can work stably.

Working Process

Automatic tube loading one by one

Color mark orientation and tube detecting

Auto Filling

Ultrasonic sealing and date coding

Cutting

Discharging

Features:

Machine could automatically finish tube feeding, registration mark identifying, filling, sealing with coding, end trimming, tube out feeding, fully automatic, save labor cost and lower production cost.

Machine is equipped with safety protection device and overload protection.

Cam indexing system could position precisely for ten working stations.

Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

Adopts anti-dripping filling nozzle.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Machine Options:

Auto Refill pump

Heating and mixing system for material hopper

Air blow system for high viscous and sticky material

316L stainless steel contact parts