VK-TS-006D Semi Automatic Ultrasonic Tube Sealing Machine

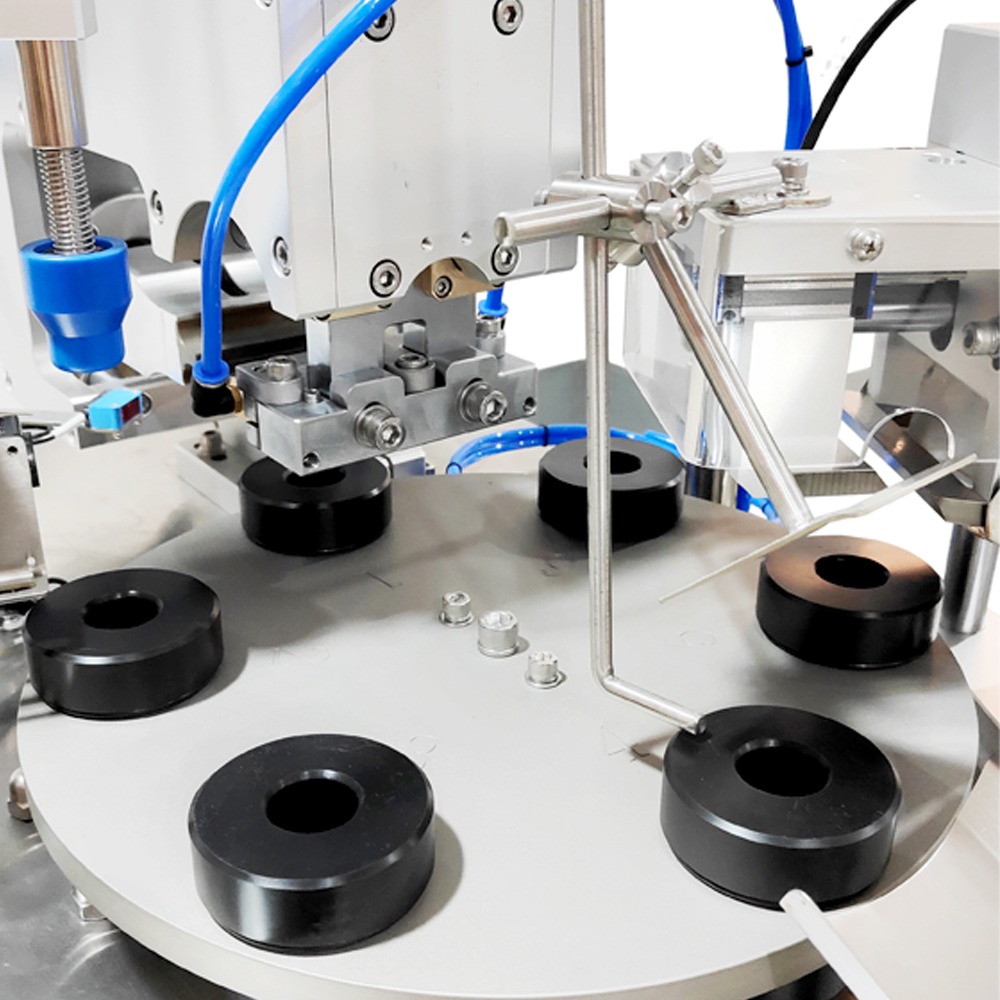

The semi-automatic rotary tube sealing machine is used for sealing of plastic and laminated tubes. This machine achieves higher output through the use of a rotary table and automatic sealing features.

Sealing Method: Ultrasonic Sealing

Output Speed: 22-25 pieces/min

Dimension: L1030*W780*H1290mm

Parameter

| Model | VK-UTS-006D |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Capacity | 22-25pcs/min |

| Sealing Dia. | 10-50mm (Custom-made available) |

| Tube Height | 50-250mm |

| Air Pressure | 0.6MPa |

| Air Consumption | 0.35m3/min |

| Dimension | L1030*W780*H1290 |

| N.W | 167KG |

- The machine is constructed from high quality 304 stainless steel

- Automatic tube orientation, sealing with coding, trimming and ejection

- Output of up to 25 tubes per minute

- PLC for controlling sealing parameters

- Ultrasonic sealing technology

- Compact footprint

Working Process

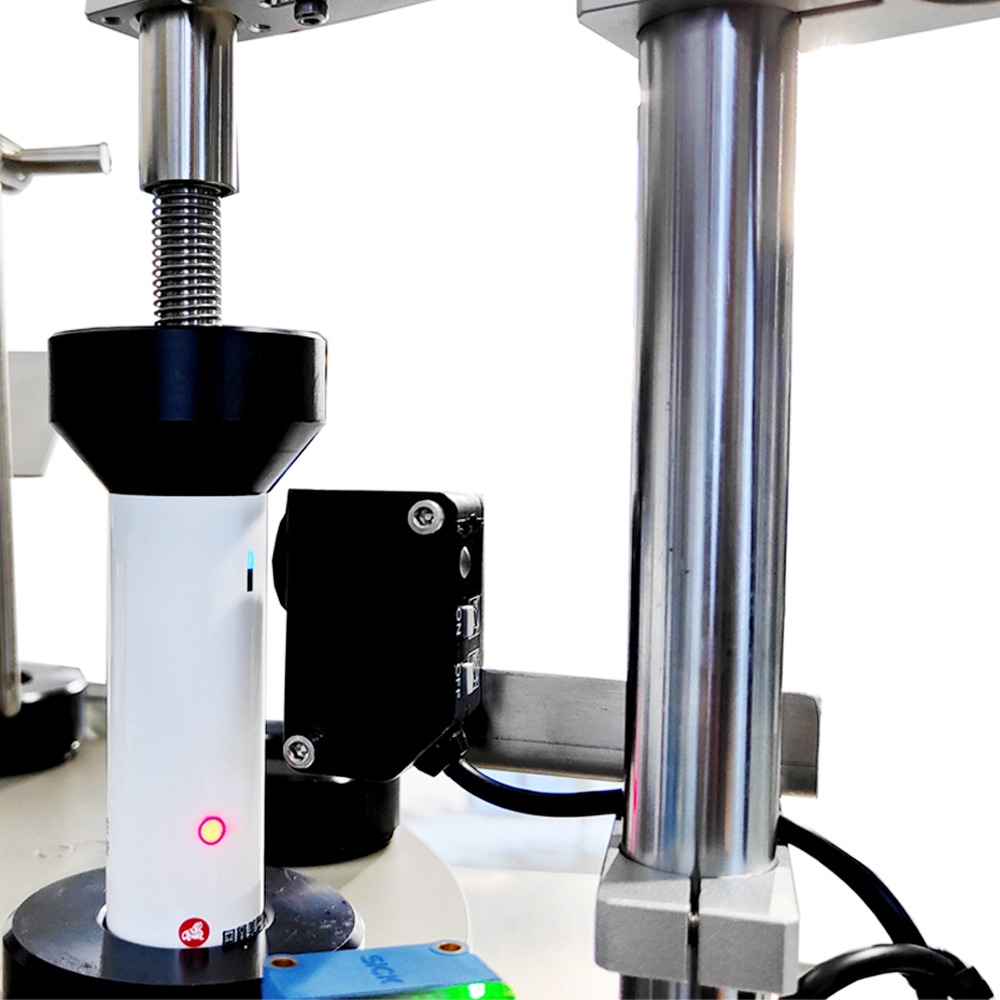

Manual tube feeding→ Automatic tube pressing → Automatic Alignment(by color mark detector)→ Ultrasonic sealing → Automatic trimming → Discharging

The sealing die applies vibrational energy to the tube end, causing frictional heating between the surface and internal molecules of the tube.

When the temperature at the interface reaches the melting point of the tube itself, the tube interface rapidly melts and fills the gap. When the vibration stops, the tube solidifies and shapes under a certain pressure, achieving perfect sealing.

The sealed workpiece meets high air-tightness and water-tightness requirements. You do not need any auxiliary materials, and the sealing process is fast, high-quality, and aesthetically pleasing. Benefits include resistance to chemicals, no pollution, and overcoming issues with adhesives or hot melt welding.

In the rotary 6-station configuration design, the turntable is responsible for driving each station in a cyclic operation. Each station is responsible for different operations, such as manual tube insertion, photoelectric identification, ultrasonic sealing, trimming, tube discharging, etc. This cyclic operation greatly improves sealing efficiency while ensuring stability and consistency in sealing quality.

Features:

1. Fast sealing speed and high efficiency:

The ultrasonic sealing machine utilizes the principle of high-frequency vibration. You can use it immediately after startup without preheating and increase production efficiency.

The sealing process is fast and accurate. The sealing strength is equivalent to that of the plastic itself, ensuring firm and aesthetically pleasing seals. The patterns are clear, with no deformation or bursting of the tube.

2. Digital intelligent frequency tracking system:

Adopting a digital intelligent frequency tracking system eliminates the need for manual frequency adjustment and enables automatic matching of ultrasonic frequencies. It has high output and low noise, effectively protects the mold, has stable performance, and has a long service life.

3. Wide range of applications:

The versatile ultrasonic sealing machine can adapt to tubes of different specifications and materials. We only need to change the tube holders when sealing tubes of different diameters.

4. Easy operation and a high degree of automation:

Using a PLC touch screen, the operation is simple and easy to understand. We can control alignment, sealing, trimming, and discharging individually, increasing automation and enhancing stability and control in the production process.

5. Energy-saving and environmentally friendly:

Because the ultrasonic sealing process requires no preheating and consumes minimal electricity, it has the advantages of energy saving and environmental protection. Furthermore, the sealing process reduces environmental pollution because it requires no auxiliary materials.

Application:

The application scope of ultrasonic sealing machines is extensive, especially suitable for PE, PVC, and PP plastic tubes.

Machine Options:

Tube holders for different diameter