VK-UTS-007 Semi Automatic Ultrasonic Plastic Tube Sealing Machine

This is a tube sealing machine. It adopts ultrasonic waves to seal the plastic, aluminum-plastic, and soft compound tubes. It is available to stamp an 8-digit date on the seal with a set of number dies. It is widely used in the daily chemical, food, and cosmetics industries. It can be equipped with date coder to make it achieve to seal and date code at the same time. reduce your production process and cost.

Sealing Method: Ultrasonic Sealing

Output Speed: 8-15 pieces/min

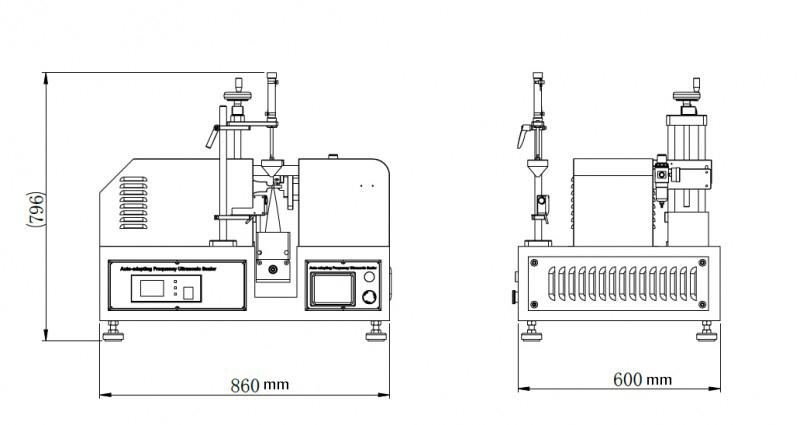

Dimension: L850*W600*H640mm

Parameter

| Model | VK-UTS-007 |

| Frequency | 20kHz |

| Power | 2600W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Capacity | 8-15pcs/min |

| Sealing Dia. | 13-50mm (Custom-made available) |

| Tube Height | 50-210mm |

| AirPressure | 0.5MPa |

| Dimension | L850*W600*H640 |

| N.W | 110kgs |

- With touch screen control panel, each function can be controlled easily according to this panel. This is good for debugging machine before using it. The imported chip and high quality circuit board makes the machine work stably.

- With sealing and cutting function, the cutting blade is made of imported material, ensure the edge will be cut neatly, improve production quality. It can also be equipped with date coder to print production date or number.

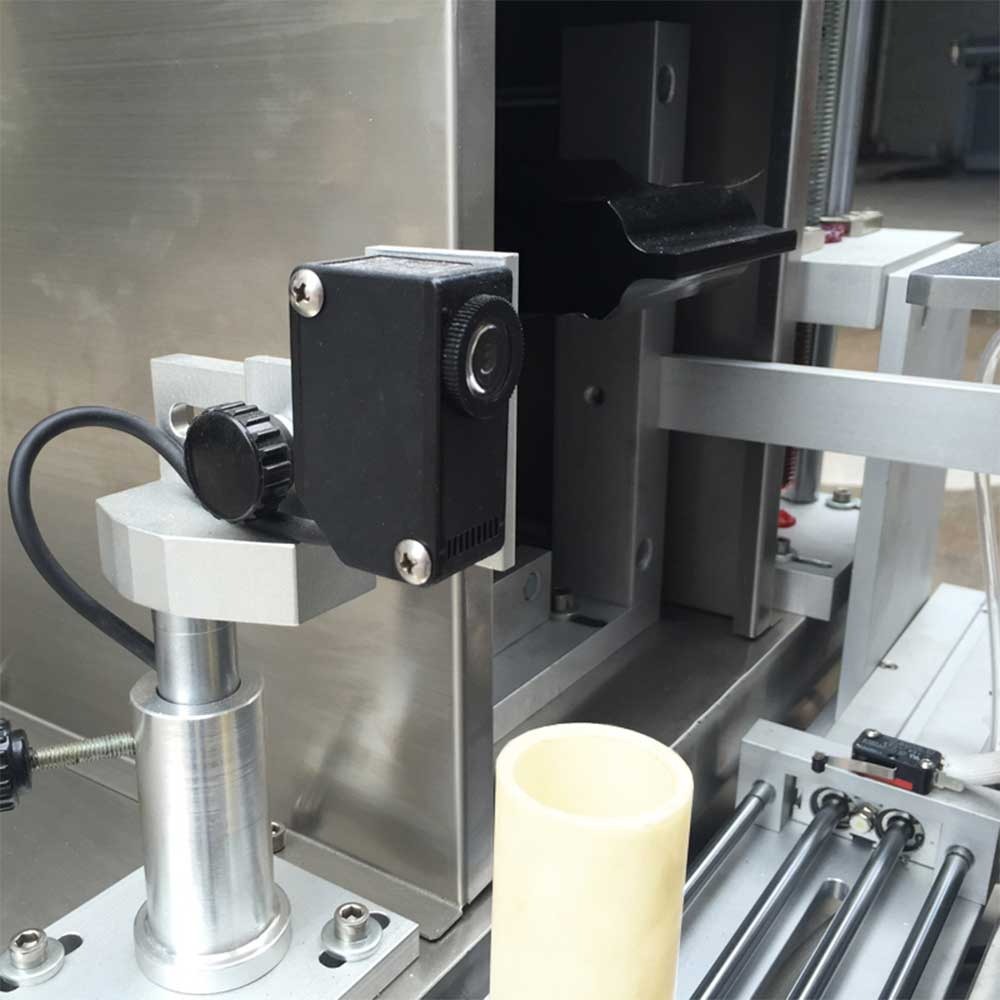

- This sensor is used to detecting the color mark and rotate the soft tube to the correct positon and ensure the next sealing work can be processed smoothly.

- The soft tube fixing mold needs to be customized according to soft tube size. This can prevent from moving tube during sealing,improves working accuracy.

- Equipped with high quality electric eye, this is designed for detecting soft tube and control the machine to start sealing and coding, improves working accuracy.

Working Process

Tube loading by hand

Color mark orientation

Ultrasonic sealing and date coding

Cutting

Features:

Table top, practical and compact design, very convinient to work with customer exsiting filler for start-up manufacturers, market test, or laboratory sample proofing.

Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

Manually feed the tube, press start button, machine could automatically identify the registration mark, go into the sealing station, sealing (with coding), end trimming and go out for workers easy take out.

Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

PLC with touch screen control system, providing a friendly operation experience.

Each action could be controlled independently in touch screen, friendly for adjustment between different tubes. Workers could use one tube only to set all the positions, saving much time and material.

"Panasonic" high sensitive sensor with a stepping motor, could track the registration mark precisely.

Coding mould is slot position design, when replace the date coding, no need to readjust the balance.

Quick adjustable lifting bracket by handwheel, could adjust based on different tube height.

Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

Safety acrylic cover, more safety and beautiful, anti-clamping hands.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube sealing.

Tube Type: plastic soft-tube, aluminum plastic laminate tube.

Machine Options:

Tube holders for different diameter