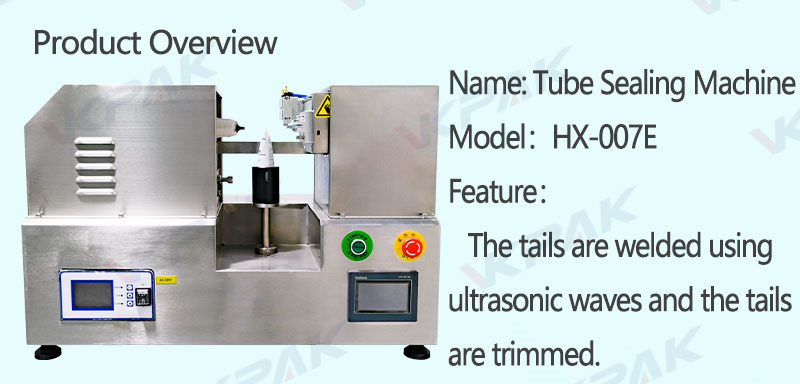

VK-UTS-007E Manual Tube Sealing Machine

This machine is suitable for sealing soft tube like toothpaste, sun cream, hand cream, shampoo, etc. It is with cutting function, which can cut off the needless tube after sealing. The machine can be equipped with date coder, which can help to print batch or production date on the tube. Save labor cost and improve work efficiency.

Sealing Method: Ultrasonic Sealing

Output Speed: 5-12 pieces/min

Dimension: L850*W600*H650mm

Parameter

| Model | VK-UTS-007E |

| Frequency | 20kHz |

| Power | 1800W |

| Power Supply | AC220V/110V 1PH 50/60Hz |

| Capacity | 5-12pcs/min |

| Sealing Dia. | 5-50 mm (Custom-made available) |

| Tube Height | 10-250mm |

| AirPressure | 0.5MPa |

| Dimension | 850×600×650mm(0.54CBM) |

| N.W | 98kgs |

- The pneumatic pressure head applies controlled pressure to the tube’s end, ensuring a tight seal. This feature guarantees consistent and uniform sealing across all tubes, minimizing the risk of leaks or product contamination. An air compressor is required for the operation, which is sold separately.

- The cutting device, operated pneumatically, trims the excess tube material after sealing. This trimming process provides a clean and finished appearance to the sealed tubes, enhancing their visual appeal and professionalism.

- The pressure head is equipped with a slot for inserting character stamps, allowing for customized coding during the sealing process. This feature enables the addition of batch numbers, expiration dates, or other essential information directly onto the tube’s seal, enhancing traceability and product identification.

Operation Steps

1. Power on the machine and connect it to the air compressor(0.2-0.6MPa).

2. Turn on the machine.

3. Click the test button to check the current reading( 0.5-2A).

4. Set the parameters. Typically, air delay: 1.3, ultrasonic delay: 0.6 seconds, and trimming delay: 0.2.

5. Place the tube in position.

6. Press Start button to initiate the sealing process.

Features:

1. It's applicable to toothpaste, cosmetic, pharmaceutical, food, industry product and other soft tube sealing.

2. Extensional organization of the machine is made of aluminium alloy and stainless steel.

3. The working platform is easily to operate that is independent man-machine operating interface and can be two dimension direction adjustment.

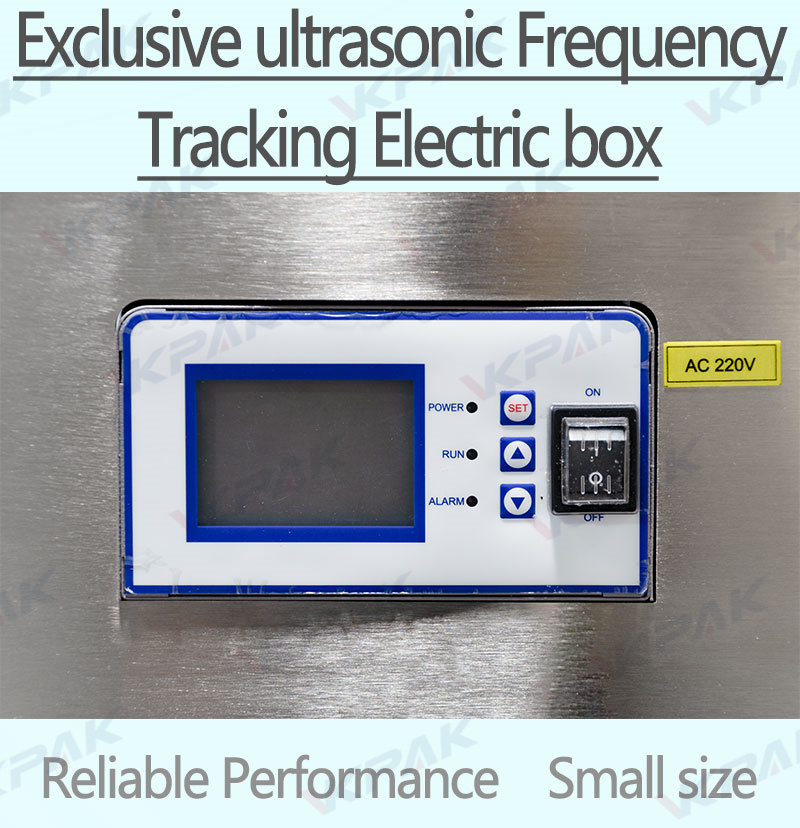

4. The ultrasound power supply adopts Taiwan movement circuitry, ultrasound parts use famous brands.

5. It's with the function of overload protection, phase difference protection, and power-fail protection

6. The ultrasound output power is big enough to ensure the sealing quality of different kinds material and specifications soft tubes.

7. It's with the function of automatically cutting.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube sealing.

Tube Type: plastic soft-tube, aluminum plastic laminate tube.

Machine Options:

Tube holders for different diameter